2025.10.21:Hitachi Digital Services AI and GenAI-Powered Digital PLM and Digital Thread (Commentary)

Enabling Transformative Outcomes Across Products, Operations, and Assets

Takeaways

- As part of the broader Hitachi group, Hitachi Digital Services (HDS) benefits from real-world industrial validation and global scale. HDS can deliver deep domain expertise and digital integration across ET–IT–OT and AI. This foundation ensures rapid, reliable deployment and measurable transformation at scale.

- HDS has identified more than 60 impactful use cases for AI and GenAI across the Digital Thread, with 20% already deployed in production. These applications embedded in PLM reduce cycle time, improve quality, and drive innovation across design, manufacturing, quality, and service functions. GenAI enhances not just automation but also reasoning, decision-making, and orchestration.

- HDS has developed a Digital PLM Playbook that offers a framework, refined from in-house use and partner experiences, to accelerate value realization. It includes tools for strategy development, platform selection, BOM optimization, and sustainability tracking, enabling organizations to move from vision to execution efficiently.

- From automated inspections to predictive maintenance and multilingual knowledge assistants, HDS’s GenAI agents enhance productivity and reduce human error. The architecture supports secure, scalable deployment across PLM, ERP, MES, and service systems. These solutions enable smarter, faster, and more resilient operations.

Industry Challenges

Introduction

For decades, industrial enterprises have struggled to bring new products, systems, or capital projects to market on time and within budget. Industry studies consistently reveal that most capital projects fail to meet time and cost expectations.[1] Among those that do go live, approximately two-thirds underperform, falling short of their intended business goals.[2]

The reasons are well known yet remain stubbornly persistent: disconnected data sources, siloed processes, and incompatible tools slow collaboration and erode decision quality. Complex product portfolios stretch engineering resources thin, while outdated legacy infrastructure resists integration with modern solutions. These factors combine to create friction at every stage of the lifecycle—from early design to long-term service and maintenance.

These challenges are intensified by the following emerging pressures:

- Sustainability requirements now demand real-time traceability of emissions, energy, and materials across the full lifecycle.

- Customer expectations for defect-free, reliable, and sustainable products continue to rise.

- Workforce transitions erode institutional knowledge, particularly in maintenance and operations.

- Rapid regulatory change forces reactive compliance instead of proactive strategies.

The result is a widening gap between strategic ambition and operational reality. Digital pilots stall, and enterprises struggle to scale initiatives into sustained ROI.

Digital PLM and Digital Thread Specific Barriers

Even organizations that have adopted Product Lifecycle Management (PLM) platforms often find their systems constrained by legacy processes. Manual handoffs between engineering, manufacturing, and service create delays and increase the risk of errors. Documentation stored in disparate systems and formats prevents rapid retrieval of information, slowing both quality assurance and field service responsiveness.

A lack of unified visibility across functional domains makes root cause analysis more difficult, particularly when defects span multiple disciplines or geographies. Persistent gaps in Bill of Materials (BOM) synchronization, change management workflows, and feedback loops inhibit continuous improvement.

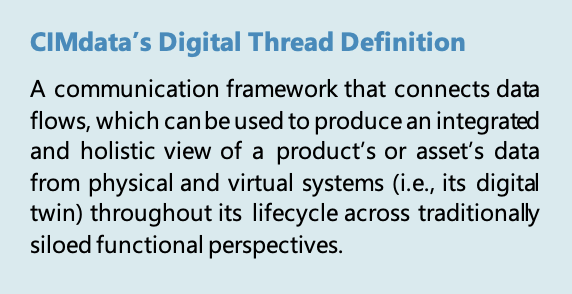

In essence, the promise of the digital thread—a connected, authoritative source of truth spanning the entire lifecycle—remains unfulfilled for many manufacturers.

Emerging Pressures

Operational and technological barriers are increasingly intensified by powerful external forces that companies cannot afford to ignore. Sustainability compliance now demands full lifecycle visibility into materials, emissions, energy consumption, and waste, requiring not only accurate reporting, but also real-time monitoring and traceable data across the value chain.

At the same time, customer expectations are rising. Products must deliver higher quality, greater reliability, and longer service life, with minimal tolerance for defects or delivery delays. Meeting these standards consistently places significant demands on both production systems and supply chains.

Workforce transitions add another layer of complexity. Retirements, turnover, and persistent skills gaps threaten to erode critical institutional knowledge, particularly in specialized roles required to support maintenance, engineering, and operations. The loss of this expertise can slow problem-solving and hinder innovation. Compounding these pressures is the rapid pace of regulatory change. Standards and compliance requirements are evolving faster than many organizations’ systems can adapt, forcing reactive responses rather than proactive strategies. Without a coordinated, integrated approach, these pressures can quickly transform small inefficiencies into systemic competitive disadvantages.

What the Market Needs

To overcome persistent challenges and unlock the full potential of digital transformation, enterprises need more than isolated technology deployments or short-lived pilot programs—they require a disciplined blend of best practices, advanced enabling technologies, and operational rigor—a key element in the implementation of a closed-loop digital thread strategy that spans the entire product lifecycle, from initial concept and design through supply chain coordination, production execution, in-field service, and through life. When executed effectively, this continuous flow of data creates a unified source of truth. This enables decisions to be informed by real-time feedback and cross-functional collaboration, allowing for informed choices.

To realize this vision, companies must take a holistic approach that combines technological advancement with strategic foresight. AI and generative AI copilots should be deployed not to replace human expertise, but to augment it across every stage of the product and operations lifecycle. These capabilities should be supported by a modular, platform-agnostic architecture that seamlessly integrates with existing enterprise systems—such as PLM, ERP, MES, CAD, and SLM—while avoiding the limitations of vendor lock-in.

Equally important is the need for scalable models that allow organizations to move confidently from initial proof-of-concept to full-scale enterprise deployment, guided by well-defined ROI milestones. This transformation must be underpinned by strong governance structures, rigorous security protocols, and responsible AI practices to ensure data integrity and ethical compliance. Ultimately, sustainability cannot be an afterthought; companies must integrate ESG and regulatory metrics throughout the entire lifecycle to drive meaningful environmental and social outcomes without compromising operational performance.

Hitachi Digital Services Solutions

Strategic Frameworks & Accelerators

At the core of HDS’ approach is the Digital PLM Transformation Playbook, refined from decades of in-house use and partner engagements. This framework uses a structured methodology to evaluate organizational performance, establish priorities, and implement digital transformation with confidence. Tools include ROI/maturity models, lifecycle assessment (LCA) frameworks, energy optimization, and material reuse tracking—ensuring sustainability and profitability go hand in hand.

GenAI Architecture & Capabilities

HDS deploys an advanced GenAI architecture that leverages Agentic Retrieval-Augmented Generation (RAG) systems to enable powerful, context-aware AI agents across enterprise processes. These systems support document search, Q&A workflows, defect review, dashboards, and decision orchestration across PLM, ERP, MES, and service platforms. Complementing the RAG systems, HDS offers a suite of industrial co-pilots that augment human decision-making and operational efficiency:

- GenItem.ai: Generates intelligent items from CAD data, links requirements and DFMEA, and accelerates validation.

- SmartChange.ai: Enhances change workflows using AI to improve speed, accuracy, and decision-making.

- SmartBOP.ai: Automates Bill of Process generation to enable consistent and scalable manufacturing planning.

- SupplierSentinel.ai: Monitors supplier risk in real time using ESG factors, news, and performance analytics.

- HDPLMSmartGPT: Reuses institutional knowledge across PLM functions to reduce duplication and accelerate innovation.

- GenSei-X: A SCADA-integrated agent that captures operational knowledge, facilitates maintenance planning, and improves real-time decision-making.

- Inspection Copilot: Utilizes computer vision, robotic process automation, and multilingual natural language processing to streamline inspection workflows, detect anomalies, and reduce human error.

Together, these GenAI capabilities create a connected, intelligent environment in which AI agents actively support engineering, manufacturing, quality, service, and sustainability activities, transforming raw data into real-time insight.

Cross-Lifecycle Use Cases

As shown in Figure 1, HDS solutions address the full product lifecycle:

- Design & Engineering—CAD parametric modeling, model-based definition (MBD), BOM optimization, and simulation-driven design.

- Manufacturing—predictive quality, real-time production monitoring, worker safety modeling, and closed-loop scheduling.

- Quality—automated audits, compliance dashboards, and multilingual QA documentation.

- Service & Maintenance—predictive maintenance, anomaly detection, and automated work order creation.

- Sustainability—AI-driven reporting of water, carbon, and energy KPIs to meet ESG goals.

(Courtesy of HDS)

Case Studies

Case Study 1: Automated Quality Inspection (AQI) Copilot

A global discrete manufacturing company faced delays and high costs from manual inspections. HDS deployed its AQI Copilot, using robotics, computer vision, and GenAI-driven workflows. The result: defect detection rates improved significantly, inspection times dropped, and costs were reduced by more than 20%. The solution also integrated seamlessly with SAP DMC and MES platforms, ensuring enterprise-scale adoption.

Case Study 2: GenSei-X Maintenance Copilot

In the manufacturing sector, operators struggled with downtime due to siloed data and workforce skill gaps. HDS’ GenSei-X copilot integrated SCADA/PLC data with MES and ERP systems, automatically creating work orders, summarizing abnormalities, and guiding root cause analysis. This reduced unplanned downtime, cut maintenance costs, and preserved institutional knowledge, directly addressing the skills gap challenge. See Figure 2.

(Courtesy of HDS)

Conclusion

HDS is redefining industrial innovation with AI- and GenAI-powered Digital PLM and digital thread capabilities that span products, operations, and assets. Backed by decades of domain leadership and one of the world’s most complete PLM/OT test environments, HDS delivers measurable outcomes for the most complex industrial enterprises. HDS’ ready-to-deploy frameworks, industrial agents, and full lifecycle support empower organizations to accelerate innovation, boost profitability, and achieve global sustainability standards. The fusion of Hitachi’s OT, IT, and ET expertise enables faster, more reliable transformation across the product value chain.

GenAI is not a future concept—it is delivering value today in engineering, manufacturing, and service operations. HDS provides organizations with advanced solutions such as robotics simulation, immersive visualization, predictive maintenance, and multilingual knowledge assistants, enabling a transition from reactive approaches to proactive, data-driven optimization. The HDS Digital PLM Playbook provides a structured path from vision to enterprise-scale deployment, while modular, agentic architectures ensure flexibility, scalability, and ROI transparency.

CIMdata recommends that companies seeking to advance their digital thread and PLM capabilities evaluate HDS’ integrated ET-IT-OT approach, its AI and GenAI solutions, and its proven transformation methodology. With the right strategy, organizations can turn the digital thread into a durable competitive advantage—one that drives innovation, profitability, sustainability, and market leadership in an increasingly complex industrial landscape.

[2] Research for this commentary was partially supported by Hitachi Digital Services.