2025.9.30:Shapr3D: Democratizing CAD Across Organizations (Commentary)

Key Takeaways

- 3D CAD is prevalent in product development, but replacing outdated technology and manual processes can significantly enhance and expand enterprise workflows across the lifecycle especially with non-traditional users.

- Workflows that are often out of scope for product engineering and 3D include early-stage design, concept development and ideation, design review, digital validation and prototyping, tooling design, process engineering, maintenance, and prototyping.

- Providing an accessible, high-value solution to capture product definition and non-product data across the enterprise expands cross-team collaboration, improves traceability, and enriches the digital thread, driving individual and organization productivity.

- Shapr3D, a modern, accessible (easy to learn, easy to use) Parasolid-based CAD solution, runs on tablets, desktops, laptops, and Apple Vision Pro, enabling collaborative 3D design for traditional and non-traditional users.

Introduction

While 3D CAD solutions have been around for decades, they have typically been used for product design and documentation by trained engineering designers. Downstream access is often only available via PDF drawings containing 2D views and annotation derived from the 3D data or simplified, read-only, 3D data in a viewing tool. This type of access is useful but can be dramatically improved by allowing more people to access data using the native CAD solution. Unfortunately, the license cost and user interface complexity of traditional CAD tools limits upstream and downstream access to people with a tool license and considerable training.[1]

Furthermore, marketing, test lab, shop floor, and field service groups often use a wide variety of 2D tools including MS PowerPoint! to capture information and communicate. Unfortunately, these tools are not designed to created 3D data, operate in silos, and are difficult to incorporate into a company’s product definition let alone digital thread.

In CIMdata’s consulting work, we advise that companies take a holistic view of their product lifecycle and digital thread if they want to maximize their business performance. Ideation, conceptual design, prototyping, validation, all parts of the product, and related processes must be included in the digital thread. At a high level, businesses all face similar pressures as shown in Figure 1.

Figure 1—Pressures Faced by Modern Businesses

(CIMdata)

Many companies focus on cost-cutting to address business pressures, but this unsustainable approach often yields diminishing returns. Instead, they should prioritize optimizing the cost-to-value ratio through product and process innovation, leveraging 3D CAD as a cornerstone for defining physical products. Beyond cost efficiency, advanced 3D CAD platforms enable broader access to design capabilities, acting as catalysts for innovation. By offering intuitive interfaces and seamless integration of 3D data into collaborative workflows, these tools empower diverse teams to drive creativity and sustainable innovation across people, processes, and technology.

Technology Requirements to Expand 3D Usage

To expand 3D design adoption beyond traditional CAD users and drive enterprise-wide innovation and productivity companies require solutions that address both technical and business challenges. A successful 3D CAD solution must enable seamless communication, foster collaboration, and integrate with modern and legacy processes while remaining accessible to diverse users. The following attributes outline the essential technology requirements for such a solution, ensuring it empowers both existing CAD users and non-traditional stakeholders—such as product managers, manufacturing teams, and quality assurance personnel—to leverage 3D data effectively.

- Easy to Learn and Use—To expand 3D usage, the solution must feature an intuitive interface that minimizes training time for non-CAD experts. Touch- or gesture-based controls, akin to mobile apps, enable users like field engineers or quality inspectors to create or review designs with minimal training. This accessibility enhances communication, allowing cross-functional teams to collaborate on designs and drive productivity through faster iterations.

- Robust—The solution must handle complex geometries and large assemblies reliably to support diverse products. A robust 3D CAD platform should leverage proven modeling kernels to ensure precision for intricate designs, such as molded parts or automotive subassemblies, while maintaining performance for assemblies with hundreds of components and interoperability. Stability under heavy workloads, validated by industry benchmarks, ensures trust for both engineering and non-engineering users.

- Broad Range of Device Support—To democratize 3D access, the solution must operate across laptops, desktops, tablets, mobile devices, and emerging platforms like AR/VR headsets, and be compatible with their respective operating systems (i.e., Windows, MacOS, iOS, Android, and visionOS). Cross-platform data compatibility enables seamless collaboration across globally distributed teams.

- Collaborative—Effective 3D expansion requires real-time collaboration to bridge technical and non-technical teams. Cloud-based platforms with version control, shared model access, and integration with communication tools (e.g., enterprise messaging apps) enable seamless feedback loops.

- Compatible with Legacy Data and Processes—To integrate with existing PLM and ERP systems, the solution must support standard data formats (e.g., STEP, IGES, STL) and legacy processes. This minimizes disruption for companies transitioning to modern design practices.

- Enables Additive Manufacturing and Modern AR/VR Processes—The solution should support innovative processes like additive manufacturing, and AR/VR visualization. Export capabilities for 3D printing and additive manufacturing optimize rapid prototyping and production of parts supporting agile development and speeding time-to-market. AR/VR integration enables virtual design reviews and training, enhancing efficiency for complex products and processes in traditional and emerging industries.

- Revamps Legacy Processes—By injecting 3D into legacy workflows, the solution accelerates decision-making and streamlines operations. Replacing 2D drawings with interactive 3D models allows marketing, manufacturing quality, service teams, and others to visualize products, parts, and assembly sequences enhancing agility, enabling faster iterations and better alignment across the product lifecycle.

- Cost-Effective—A 3D solution must be affordable to promote adoption across small-to-medium enterprises (SMEs) and extended teams in large organizations. Pricing models, such as Shapr3D’s subscription-based plans starting at $50/month, make 3D tools accessible to non-traditional users like procurement and marketing teams, as well as the previously mentioned product managers, and manufacturing, and quality teams. Cost-effectiveness ensures scalability without prohibitive upfront investments, maximizing ROI for enterprises shifting to 3D-driven workflows.

Delivering on these attributes enables enterprises to address business challenges and increase product and process innovation by expanding 3D usage. For existing CAD users, the solution enhances productivity through robust, user-friendly tools. For non-traditional users it democratizes access to 3D data, fostering collaboration and innovation. By balancing cost, accessibility, and compatibility with modern and legacy processes, a 3D CAD solution supporting these attributes drives enterprise-wide productivity and innovation.

Shapr3D: Extending 3D CAD to the Enterprise

Shapr3D was founded in 2014 in Budapest, Hungary and launched its initial product globally in 2016 on the Apple iPad Pro. The target was professional users that needed a mobile solution for 3D modeling. The solution uses a minimal, user-friendly interface inspired by Apple’s ethos, earning an Apple Design Award in 2020 for its intuitive design. Over the years Shapr3D has expanded its modeling capabilities, platform support, and streamlined workflows as well adding a SaaS option for cloud-first companies.

A successful enterprise-grade solution demands robust technology, seamless interoperability, and advanced collaboration tools beyond mere features to meet enterprise needs. Shapr3D uses the Parasolid kernel for 3D geometry and the D-Cubed constraint manager from Siemens, tools that many top-tier CAD solutions use. Hoops Exchange from Tech Soft 3D is used to provide interoperability-enabling support for native and standards-based CAD data exchanges, meshes for additive manufacturing and AR/VR, and a variety of 2D formats. Interoperability is critical as most enterprises have data in many formats so streamlining data import and export speeds processes.

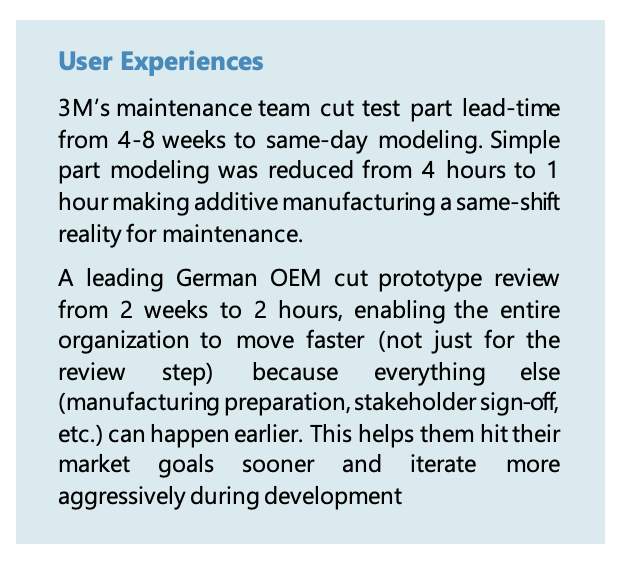

An area Shapr3D is especially proud of is their approach to streamlining modeling workflows. Areas of improvement include faster conceptual modeling, increasing design review agility, collaboration in AR/VR, speed increases from the adaptive user interface and hybrid modeling support for both parametric and direct editing techniques. Sharpr3D customers claim improvements of 20 to 80 percent depending on the workflow. CIMdata sees these claims as credible, because reducing process friction within product lifecycles can affect speed and data quality reducing errors and number of iterations. As an example, Figure 2 shows the streamlined workflow Shapr3D customers use to speed their processes by leveraging the AR/VR editing capability.

Figure 2—Streamlined Workflows for Shapr3D Customers

(Courtesy of Shapr3D)

Collaboration is critical to process improvement in modern enterprises. Shapr3D has a full-featured collaboration environment embedded within the solution which includes public and private projects, project versioning, and commenting. Design reviews can be done within the desktop solution or via a web browser. A shareable project link gives browser-based participants’ easy access. Comments are associated to objects within the model and projects can store saved views for easy navigation. Sectioning and measurements enable reviewers to get deep into part and product details. With the cross-device support an engineer in the field using a tablet can comment on a prototype issue at a customer and the conversation can immediately happen with the product team back in the office. On mobile devices with augmented reality capability 3D models can be projected into the real-world environment making it easier for non-technical people to understand the product. For people using Apple’s Vision Pro, shared sessions enable multiple people to view and edit the product in a live session dramatically shortening the design and review cycle.

Additionally, Shapr3D offers a flexible range of data management options. By default, it works with file systems on shared drives, and integrations to popular PLM solutions are available. Shapr3D also has a flexible data storage environment available for customers, including Shapr3D Cloud, private cloud options, and on-premises data storage, all managed by Shapr3D’s cloud-based Project Sync Service. As a final note, software cost is important with every enterprise. Shapr3D is priced aggressively especially considering the capabilities. They offer a freemium model which gives companies a low risk, low effort way to evaluate Shapr3D’s claims and benefits.

Conclusion

CIMdata clients never say their product design process is too fast. As CAD modeling underpins development, advanced software enhancing workflows can significantly reduce costs, time to market, and improve quality. The obvious target for these improvements is the core design team, but when looking at processes holistically, it becomes obvious that better, cost-effective access to 3D product data can have a major positive impact throughout product lifecycles.

Shapr3D leverages technology and platforms such as Siemens Parasolid and modern computing hardware to enable companies to improve their product lifecycle processes. Faster product design, improved collaboration, and faster review cycles shorten the overall lifecycle enabling organizations to innovate in both their products and their processes—the only sustainable competitive advantage. Companies looking to improve their competitive advantage by replacing their current CAD solution or augment it so 3D can be leveraged by a broader audience within their companies should contact Shapr3D.

[1] Research for this commentary was partially supported by Shapr3D.