2025.5.6:Codebeamer 3.0: AI Driven Enterprise ALM & PLM (Commentary)

Key Takeaways

- Applying AI techniques to requirements’ engineering and management throughout product development and use enables OEMs to enhance knowledge application and establish end-to-end traceability that speeds product development and upgrades.

- Modern virtual engineering ecosystems need integrated application lifecycle management (ALM) and PLM environments enabling AI to improve visibility of regulations and safety standards and ensure regulatory compliance throughout the complete product lifecycle.

- PTC’s enterprise ALM solution portfolio (Codebeamer, Pure Variants, Modeler, and RV&S) powers model-based systems engineering, requirements management, product line engineering, variant management, test management, and engineering workflows.

- PTC’s ALM solutions are integrated with their PLM system (Windchill) to help shorten time to market while improving product quality and regulatory compliance.

Introduction

CIMdata’s definition of Product Lifecycle Management (PLM) addresses the complete lifecycle of a product including related data and processes—from idea inception to requirements definition, to planning and development, to supply chain management, and then mass production and in-service performance and product upgrades. The embedded software and server-based software that complements a product are managed in Application Lifecycle Management (ALM) solutions. Comprehensive PLM environments encompass ALM capabilities that support the complete product definition and all its features—many of which contain both software and electronic/mechanical hardware. Integrated ALM has improved PLM environments by bolstering traceability across design elements, test results, regulatory requirements, and customer usage through end of life. In 2024, CIMdata published a commentary focused on PTC’s growing ALM suite of tools and their ongoing progress towards integrating ALM and PLM, their Windchill solutions.[1]

PTC’s latest Codebeamer release includes artificial intelligence (AI) capabilities used in both their ALM and their PLM solution sets. This commentary provides an overview of the Codebeamer 3.0 release and why it is delivering AI.

Codebeamer 3.0 with AI capabilities

PTC is delivering its latest advances in ALM by introducing an AI capability that helps users improve their multi-contextual understandings of the current elements of design they are working on. It does not matter whether the elements are mechanical, electronic, or software. What matters is that all disciplines share the same customer requirements and regulations, especially as they change during the lifecycle. These often change during development and use, which in turn makes continuous requirements traceability essential. The systems engineering and orchestration required to bring today’s products to market requires an environment which is agnostic to specific engineering disciplines while being comprehensive as the product is being made.

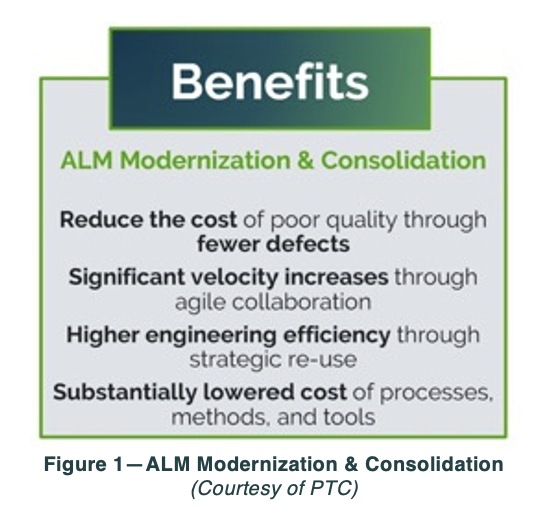

PTC’s ALM modernization and consolidation provides benefits summarized in Figure 1. Reducing the number of defects found late in the lifecycle improves quality. By adopting agile practices in all disciplines—software, electrical, and mechanical engineering—time to market is shortened as the organization’s development velocity increases. Applying best-in-class product line engineering techniques, like those available in Pure Variants, improves an organization’s efficiency by only focusing on features which customers desire to purchase. Having consistent supporting processes for risk management, issues tracking, change management, and agile practices, leads to a well-orchestrated organization applying all its proven engineering and operational skills.

There are competitive benefits of having techniques and processes that enable the exploration of candidate features that can be implemented in alternative ways across engineering domains and product families. Systems developers rely on ALM solutions to manage their virtual engineering ecosystem, from requirements to trade studies to virtual commissions to field issues resolution. AI may well improve the speed of discovery both in design creation and in issue solving. By combining their ALM suite (with its new AI capabilities) with their PLM suite, PTC is providing a seamlessly integrated ecosystem designed to enable faster and higher quality systems development and deployment by combining ALM and PLM digital threads.

Industry adoption of PTC’s ALM solutions continues, and the inclusion of AI tools should help expand that adoption. AVL, a renowned engine and system engineering company, uses Codebeamer and Pure Variants for test and validation management. This illustrates the broader value PTC’s ALM suite can bring to systems integration and validation. Volkswagen is expanding their ALM rollout to tens of thousands of engineers as mobility products become more software defined vehicles (SDV). Such software must be built in conjunction with the other engineering domains which provide the vehicle platform for SDVs. The AI capabilities for requirements and variant management are the same for all engineering domains and operational disciplines ensuring comprehensive lifecycle solutions.

Software Defined Products Need Integrated ALM—PLM

As the electronics and software content in all products continues to expand, ALM and PLM must work seamlessly together. Common capabilities inside enterprise processes (e.g., change management, variant planning, and risk management) must exist and span all engineering disciplines. PTC has consolidated their digital thread organization so that there is a single architecture-driven ALM-PLM integration.

Software residing in a combination of the product and in the cloud that is serving and controlling products must be managed in a systems-of-systems framework, with cooperating product lines. What resides in the cloud and what resides in an individual product will vary based on location and usage. Managing these complexities requires more than a list or requirements—it requires broad systems engineering. In fact, there is a growing need to understand requirements’ change sensitivity across a product’s service lifecycle to assure ongoing safe and reliable operation. PTC understands software defined product’s (SDP) complexity. Mr. Luca de Meo, Renault’s CEO, states that “SDP will become better and improve themselves day by day.” There is a need to move beyond the original product data management (PDM) only systems to manage development and mass production. In this environment, the utilization and support phases of a product’s life must also be managed, and in some cases may lead to new revenue opportunities as the latest applications provided on an SDP platform are utilized. Note the five key characteristics of SDPs are described in Figure 2.

Figure 2—SDP Characteristics

(Courtesy of PTC)

An always-connected SDP having its use revealed in a digital twin connected to related engineering, manufacturing, and service information will be the hallmark of the best ALM-PLM solutions.

PTC understands SDP implications and what is needed in the best PLM solution for all phases of a product’s lifecycle. PTC Modeler was the first SysML 2.0 solution for systems engineers. Appropriately, PTC has positioned this within the ALM domain where systems trade-offs happen both early in product development and in delivering product functional upgrades via telecommunications— often coined “over-the-air updates.” All engineering, manufacturing, and service disciplines need coordination and sharing of product contents and development progress. PLM users need the same awareness of system trade-offs and choices as ALM users. PTC’s deep integration of Codebeamer and Windchill is designed to deliver this important capability. Furthermore, they are now championing a single digital thread architecture enabled by AI with Codebeamer 3.0 that accelerates the use/reuse of all facets regarding product knowledge.

PTC Strategy Combines ALM with PLM

PTC’s history of ALM acquisitions and their recent AI deployment in Codebeamer 3.0 helps enable faster knowledge application into all aspects of SDP engineering, manufacturing, and service. Figure 3 shows PTC’s evolution from point solutions to an end-to-end (aka lifecycle) engineering solutions platform.

Figure 3—Acquiring and Combining ALM Capabilities

(Courtesy of PTC)

Competitive SDP complexity pressures require better decisions made faster to comply with regulations. Systems engineering driven with proven models, aka MBSE, is a skill today’s engineers must embrace, regardless of their specific engineering expertise. These are required to ensure quality and sustainability across the SDP lifecycle. Modern PLM ecosystems (i.e., PTC’s Windchill), are integrating ALM capabilities (i.e., PTC’s Codebeamer 3.0, Modeler, and Pure Variants) across the complete product lifecycle, as CIMdata defines it. PTC states, “Codebeamer empowers companies to deliver innovative, safe & secure software-defined products faster and more reliably through mastering product complexities and variability with agile collaboration in the digital thread.”

Agile development practices can apply to any engineering discipline, not just software. The techniques to manage feature requests and a backlog of work with wish-to-haves and mandatory requirements is typical of all product and component development. Strategy and efficiency come into play as engineers plan a product line and reuse components across products. Figure 4 shows the ALM functions that PTC is working to improve to support software and the systems engineering techniques needed to master complexity and compliance and real-time collaboration and agility, all while improving efficiency and speed.

Figure 4—Complex products development and support services

(Courtesy of PTC)

During a CIMdata review this past winter, PTC leadership confirmed that the same framework is simultaneously applicable to all engineering disciplines, not just software engineering, and becomes essential for cross discipline collaboration—a powerful ALM-PLM ecosystem. Their consolidated digital threads focus can help enable lifecycle solutions for SDPs. PTC continues to acquire systems engineering and MBSE expertise with their just announced acquisition of IncQuery.

Conclusion

As more and more product features are enabled by software elements, ALM capabilities from PTC are being integrated with their PLM solution, Windchill. In fact, ALM capabilities are an increasingly important factor customers are considering as they expand their virtual engineering for SDP.

PTC continues their progress of enabling the digital thread across an enterprise and supporting and using SDPs from inception (systems engineering) until end of useful life (through upgrades and service). PTC’s strategic focus for Codebeamer is helping companies master complexities while innovating faster with reliable delivery. With Codebeamer 3.0’s new AI capabilities integrated with Windchill, PTC can enable a company to implement the comprehensive engineering digital thread required to efficiently design, produce, and service SDPs. As AI capabilities come to the market, it is best to work with an established ALM and PLM solutions provider where AI capabilities are available.

CIMdata recommends that companies include PTC in their evaluation and selection of ALM capabilities, especially as AI techniques are evaluated and adopted. PTC’s ALM-PLM capabilities are well integrated yielding an ecosystem to address complex multi-discipline product and agile development needs. As they have done with Windchill becoming Windchill+, a SaaS, cloud-based capability, CIMdata expects the same for Codebeamer soon.

[1] Research for this paper was partially funded by PTC.