2024.2.27:The Digital Thread: A Key Enabler for PLM Success (Commentary)

Key Takeaways

- Product complexity continues to increase and the need for improved cross-business and cross-domain collaboration is becoming more critical

- Digital transformation initiatives are driving manufacturers to create robust digital threads across their organizations.

- Effective integration of PLM data requires a rare blend of skills in business and technology.

Razorleaf is a solution provider with deep expertise in PLM and offers CLOVER―a solution for product data integration, allowing manufacturers to speed new product introductions―maximizing product margins.

Introduction and Background

Product Lifecycle Management (PLM) solutions are regarded as critical enablers for developing and maintaining products. As products become more complex, driven by increased use of microelectronics, embedded software, communications, and application interfaces, the need for PLM continues to increase.[1]

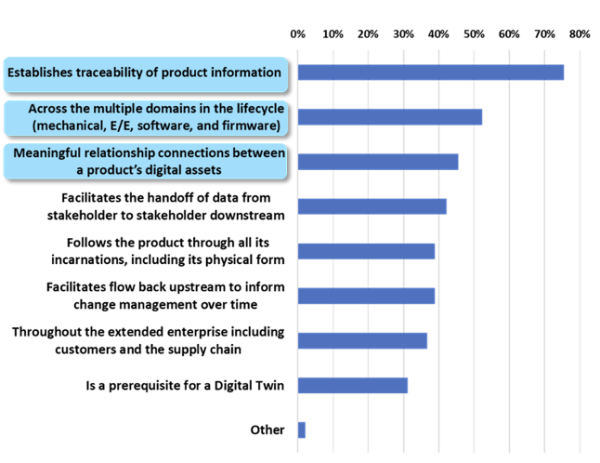

In parallel, organizations are working to digitally transform their operations to improve their ability to respond quickly to market opportunities and retain long-term competitiveness. A key element of this is the creation of digital threads aimed at streamlining processes and improving collaboration across both product domains (mechanical, electronic, software, etc.) and enterprise systems, thereby improving efficiency and agility. Research recently undertaken by CIMdata in conjunction with the Aerospace & Defense PLM Action Group has highlighted an emerging consensus for how digital threads can help manufacturers, as shown in Figure 1.

At its core, creating a digital thread is about integrating disparate systems, each with their own data and process models. Data integration is technically challenging and requires a deep understanding of the data structures underlying major systems and methods for accessing and transferring data (i.e., data flows, triggering actions, APIs, etc.). From a business perspective, a firm understanding of the context and use of data is essential to ensure that it is managed and presented in the correct way. Often in the past, this work was undertaken internally but this is becoming less feasible as technical and business complexity increases. As a result, manufacturers are turning to specialist service providers with proven products and deep expertise.

In this commentary we consider a number of critical attributes of data integration solutions that can be used to create digital threads. We also specifically highlight Razorleaf, a consulting and systems integrator specializing in PLM, that helps innovative manufacturing organizations bring new products to market. To address data integration and create digital threads, Razorleaf offers CLOVER, a family of products that enable the sharing and exchange of product information across the organization, partners, and suppliers.

(Source: CIMdata A&D Action Group Research)[2]

The Critical Success Factors Solution Providers Must Address

CIMdata has been involved in many integration projects as key elements of PLM programs we have overseen for our industrial clients. From these, CIMdata has developed the following set of critical success factors for the providers of integration solutions and services which industrial companies can use to evaluate and select integration service providers.

Focus on PLM

There are many data integration solutions available on the market today. The market is growing rapidly, and a handful of companies have seen rapid expansion in recent years. A strength of many of these solutions is their ability to connect a wide range of target systems, often with little coding effort. To achieve the necessary ease of use, their focus has been on managing relatively simple pieces of information. Generally, they do not have the capabilities, nor the expertise to take on the complex work involved in a PLM program.

As a result, industrial companies should seek out one of the few specialist data integration solution providers focused on PLM. These are organizations that have built their businesses by specializing in PLM and have acquired deep technical and business knowledge, allowing them to deploy capable solutions and achieve positive results in realistic timescales.

Productized Solution

Most integration solutions started as toolkits. These have been typically configured and deployed by the solution provider’s own consultants. Although capable, they tended to need constant monitoring and maintenance to ensure they continued to work through solution and operating system upgrades. But for robustness and organizational scalability, a fully productized solution is preferable.

A productized solution will generally come with comprehensive documentation and training materials, a support organization, regular proactive maintenance updates, and a product roadmap for the incorporation of new features. In the hands of experienced implementation consultants, a productized solution offers the predictability and robustness that industrial organizations need.

Deep PLM Solution Knowledge

A key predictor of the market success of a PLM data integration solution provider is their technical understanding of target PLM solutions. A small number of solutions dominate the PLM market and solution providers must have knowledge of one or more of them, e.g., Siemens Teamcenter, Dassault Systèmes ENOVIA, and PTC Windchill. However, there is a growing list of solutions now vying for market position, knowledge of which would also be beneficial to solution providers, e.g., Aras, Arena (acquired by PTC), Autodesk’s Autodesk Fusion 360 Manage with Upchain (Upchain acquired by Autodesk), Propel, OpenBOM, Duro, and others. An additional layer of complexity is created as legacy on-premises solutions move to the cloud. While many PLM solutions offer very similar capabilities on their different versions, there may be critical differences in underlying data models and configurability that will require additional specialist knowledge and experience.

While deep knowledge is typically acquired by working directly with a target PLM solutions, a relationship with the PLM solution provider, either formal or informal, is also beneficial. This can ensure that the data integration solution provider benefits from training and support for the PLM solution and also direct access to solution experts.

Geographic Coverage

For many industrial companies with operations in only one region of the world, a data integration solution provider limited to the same region is perfectly adequate. However, for industrial companies operating in multiple regions or having a global supply chain, a data integration solution provider with a similar regional spread becomes even more important. This can simplify efforts with local availability of solution experts and support for local languages.

Data integration solution providers typically provide this geographic coverage via their own operations and subsidiaries in major regions and countries or via a partner network in smaller regions. Fast Implementation & Reasonable Pricing

As in all areas of information technology (IT) services, customers expect fast implementation and reasonable pricing. Meeting these expectations is important not just for customer satisfaction but also for achieving the overall PLM project return on investment (ROI). Therefore, a key characteristic of successful data integration solution providers is their ability to accurately scope a project based on past experience and to offer a realistic and competitive price based on the value being delivered by the integration solution.

Digital Transformation

As previously mentioned, a deep understanding of the working processes of industrial companies is essential for successful data integration solution providers. Going forward, however, that knowledge must be complemented by familiarity with digital transformation, the dominant theme for improving future business value. This includes understanding the weaknesses of current approaches, likely involving the use of spreadsheets and other documents, simple collaboration tools, and legacy systems, and how they can be transformed by PLM solutions, especially those moving to the cloud.

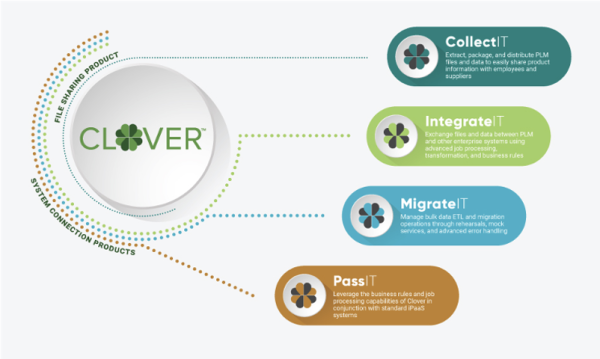

Razorleaf Clover: A Complete Solution for Integrating PLM Data

To meet the data integration needs of industrial companies and provide support for creating digital threads, Razorleaf offers CLOVER, a productized solution proven in many large PLM implementations. Having grown from an initial focus on integrations, CLOVER is a family of products (see Figure 2) that enables the exchange of product information across the organization, partners, and suppliers. According to Razorleaf, with CLOVER, organizations can reduce development costs, streamline processes, and accelerate innovation―ultimately extending the value of an organization’s investment in PLM and other enterprise solutions.

Architecturally, the CLOVER platform has a number of key attributes that differentiate it from similar products:

- Extensible (via programming plug-ins), allowing complex corner-cases to be addressed.

- Designed to handle complex PLM data structures and large files.

- Available for deployment on-premises, cloud-based, and in hybrid environments, making it suitable for all types of organizations and use cases.

(Courtesy of Razorleaf)

CLOVER CollectIT allows users to extract and package PLM-managed files and data for use outside of PLM. This web application enables staff to view or extract product information (including part and BOM representations, related CAD files, and technical documents) for distribution to employees, suppliers, and clients. CollectIT automates the extraction process for creating bid packages, product specifications, end item data packages (EIDPs), and technical data packages (TDPs).

CLOVER IntegrateIT enables PLM connections to enterprise systems, creating digital threads for improved collaboration and improved, more reliable data exchange. IntegrateIT provides multiple out-of-the-box (OOTB) PLM integrations that simplify the way files and data synchronize between PLM, PDM, ERP, CRM, MRP, and other enterprise systems. With IntegrateIT, product data and information are delivered to every area of the organization to ensure data accuracy, reduce implementation costs, and mitigate risks.

CLOVER MigrateIT enables the bulk transfer of files and data between one PLM and other PLM systems quickly and with less effort than OOTB or generic Extract/ Transform/Load (ETL) tools. MigrateIT uses the CLOVER job processing architecture to orchestrate environment preparedness, data analysis, and pre-migration rehearsal, along with batch processing, and error handling.

CLOVER PassIT provides an interface between messaging platforms and PLM solutions. PassIT distributes required files and data to other systems based upon what is needed and previously defined in the integration Platform as a Service (iPaaS) APIs. PassIT handles complex data transformations, file rendition creation, product revision selection, and other process-oriented logic without requiring complex API changes. PassIT has been designed to boost end-point performance and relieves the service bus from complex operations.

Razorleaf Background

Razorleaf is a consulting and systems integrator specializing in PLM and MES that helps the world’s most innovative manufacturing organizations bring new products to market. With a deep understanding of PLM, industrial processes, and digital transformation strategies, Razorleaf partners with its clients to connect products and processes across the digital enterprise to drive more value. Led by a highly skilled and seasoned team of experts across the United States, Europe, and Southeast Asia, Razorleaf offers comprehensive consulting, implementation services, and proprietary software products focused on gaining business efficiencies around PLM, MES, integration, test automation, and model-based strategies.

Conclusions

Data integration is becoming increasingly important as digital transformation initiatives drive manufacturers to create robust digital threads across the organization. Often these integrations are relatively simple and have been built by the IT organization, either from scratch or using commercially available middleware tools. But with a focus on digital transformation, manufacturers now want to be able to access a much wider range of information and put it into a product context inside PLM.

The effective integration of PLM data requires a rare blend of business and technical skills. A firm understanding of product digitalization processes is essential to ensure that the integrity and context of critical product data is maintained. CIMdata believes manufacturers can benefit by utilizing specialist service providers with proven products and deep expertise.

Razorleaf is a consulting and systems integrator specializing in PLM with deep expertise in data integration. CIMdata is impressed with Razorleaf’s CLOVER, a family of products that enable the exchange of product information across the organization and with partners, and suppliers―speeding new product introductions and maximizing product margins. CIMdata encourages manufacturers looking to improve their connectivity and data integration across their enterprise landscape to consider Razorleaf’s CLOVER solution.

[1] Research for this commentary was partially supported by Razorleaf.

[2] https://www.cimdata.com/en/aerospace-and-defense/publications/digtaltwin-digitalthread