2024.2.1:Efficient Asset Information Management (Commentary)

Addressing the Challenges of Managing Large, Complex Infrastructure and Assets with Secure Collaboration

Key Takeaways

- The Architectural Engineering and Construction (AEC) and Engineering, Construction, and Procurement (EPC) industries do a poor job of handling large numbers of suppliers and providing secure collaboration across the lifecycle of their assets and related information, resulting in higher costs to owner/operators.

- Asset Information Management (AIM) is broader than Building Information Management (BIM) and focuses on managing and maintaining assets throughout their lifecycle while enabling a sustainable collaborative environment between the assets and their suppliers across multiple domains.

- AIM must manage assets and their digital twins under configuration control and ensure secure collaboration with all asset suppliers, providing traceability and end-to-end connectivity across a digital thread.

- Eurostep’s ShareAspace iAIM is based on open standards that enable complex operations to manage assets across their lifecycle and ensure they can continually be optimized.

Introduction

Historically, the AEC and EPC industries have been inefficient in handling the large ecosystems and secure collaboration required for the design, construction, and operation of large facilities and infrastructure. This has resulted in long-term higher costs for owner/operators. Most owner/operators struggle to manage their assets because their view of the asset is too narrow―often with a limited understanding of what it takes to manage an asset across its lifecycle. Unlike most industries, the AEC and EPC industries are less connected between owner/operators and their many diverse suppliers.[1]

They tend to focus on BIM in design, Product Information Management (PIM) in construction, and AIM in operations and maintenance―each with its own focused processes and data architectures. This results in issues with data handover and real-time updates. Unlike consumer product-oriented industries, AEC and operations (AEC/O) suffers from the sheer volume of tasks, a lack of accountability, poor collaboration and communication, and lack of strong change management, resulting in late-stage changes, poor interface management, and rigid operational processes during maintenance.

Complex Infrastructure Requires Asset Information Management

Managing large infrastructures such as process plants, power plants, airports, and linear infrastructures such as highways and railways lack efficiency due to poor collaboration in design, construction, operation, and maintenance. The tools and processes used are focused on a specific phase and do not employ a global through-life perspective.

Within the AEC industry, BIM is used for design, providing a 3D model that facilitates collaboration among architects and engineers and is referenced during the construction phase. A BIM model primarily contains geometric and spatial data useful in construction of some aspects of a plant or large project, but functional and system breakdowns are often overlooked. Large complex plants and infrastructure incorporate systems and equipment from many diverse suppliers, each using different design packages at many different release levels. This creates tremendous complexity (e.g., multiple data architectures, development and testing processes, attributes, metadata, etc.) and can result in vendor lock-in for an owner/operator that attempts to rely on a single proprietary software solution.

BIM models encompass a limited set of information and are typically used by a single company or perhaps a partnership of companies, but usually constrained to a portion of a large complex project. BIM models do not contain all the detailed data required for the comprehensive management of assets during their operational life. Some EPCs may opt to use database-driven plant design software with more of an emphasis on piping and electrical systems, which can work well during design within a given scope. Other OEM equipment providers will deliver 3D models in various CAD formats, often not compatible with the plant design tools/formats used by the EPC. Many AEC oriented suppliers use BIM, Autodesk drawings, or other tools. Combine all of this and it creates major issues during turnover and final handover with respect to ongoing collaboration, traceability, and the enablement of digital twins (digital representations of up-to-date physical assets).

AIM is much broader than BIM. It is designed to manage assets across multiple domains throughout their lifecycle while enabling a sustainable collaborative environment by managing the assets and the suppliers of those assets. AIM must enable AECs, EPCs, and owner/operators to view assets from multiple perspectives (i.e., design, construction, operations, engineering services, safety, maintenance, geography, etc.). AIM has an important financial component as well. After handover, next to safety and regulatory, the primary goal is to operate the plant or large infrastructure as cost effectively as possible. If you do not have control of the costs related to all aspects of the assets, you will be missing opportunities to increase operational efficiency and lower associated costs.

Digital Twins for Infrastructure and Capital-Intensive Plants

A primary aspect of managing physical assets is to make sure they are up to date, with all changes under configuration control. Within a large complex plant with many different design sources from many different organizations, this can be very complex. Today, many owner/operators are attempting to leverage digital twins to optimize their assets, operate more efficiently, and understand why maintenance and upgrade decisions were made, so they can improve their operations.

A digital twin is a virtual presentation (digital surrogate) of a physical asset that takes advantage of the data flow to and from these physical assets to maintain an accurate up-to-date configuration of the asset. This improves operations by generating valuable insights, assisting in guiding the automation of complex processes, and monitoring and controlling the physical assets.

Managing digital twins of assets in a large complex infrastructure with many authoritative sources of information, requires an AIM capability that not only manages ongoing design and maintenance changes, but also maintains the asset under configuration control. To do this, the AIM capability must also enable secure collaboration among the managed systems, suppliers, and service providers ensuring traceability and end-to-end connectivity.

The digital thread or digital web is a framework of information nodes that connect the information to the digital twin. Each node contains information critical to maintaining the asset. This can range from requirements to metadata, models, design, analysis, maintenance, operational information, and more. It represents all the decisions made throughout the lifecycle of the product and essentially answers “how” and “why” each decision was made. More and more assets are now capable of producing Internet of Things (IoT) data that can flow from many physical assets to many collection points. This necessitates that the AIM solution be able to handle secure collaboration of IoT data to enable the flexibility required to operate an “as-running” infrastructure as sensors, edge devices, and organizations will change over time.

Data Governance

There is a difference between managing assets and asset management. Managing assets is a tactical day-to-day operational activity such as maintenance. Whereas asset management is a more systemic approach that involves governance, utilization, strategic planning, as well as operations, maintenance, and all aspects of the asset throughout its lifecycle. The challenge of managing any large, complex infrastructure is that there are many sources of truth and many domains to consider, each using their own vocabulary, information formats, and specific IT platforms. There is a tendency to think a software solution solves the asset management challenge, but this is not just an IT problem. There is no asset management (as defined in ISO 55000 family of standards) without proper strategy, configuration, and data governance.

Data governance doesn’t just apply to operations. It must be applied to all areas including the maintenance and financial aspects of the assets. The asset, process, technology, organization, and people will all change over time. And the amount of data and complexity of the assets, processes, and technology will only increase. Therefore, strong data governance is critical to successful asset management.

Data governance is required across all data models to be effective. Open standards have an edge in defining the built asset operational model, as the tedious task of defining the semantic scope for every concept is typically shared among industry partners working with the open standard. CIMdata believes that standards-based data governance over complex operations that are constantly evolving is a must.

Model-Based System Engineering

Model-based system engineering (MBSE) is not often thought of in the AEC/O industry. It is more traditionally used in the systems engineering of complex products in the aerospace and automotive industries. It is a way to manage complex systems of systems using visual models that show the relationships, interactions, and components that engineers collaborating across multiple domains made up of different types of data and processes need to understand. These models help engineers understand how the systems operate within certain constraints, providing a better understanding of potential bottlenecks. This allows constraints to be identified earlier in the process, allowing for more informed decisions to mitigate potentially costly limitations.

MBSE can be used within the AEC/O industry in all phases of the lifecycle including design, construction, operations, and maintenance. By using MBSE, owner/operators can employ a structured auditable approach to identifying requirements and managing interfaces across systems that will enable better control of data and processes throughout the lifecycle of large complex infrastructures.

ShareAspace iAIM Addresses Multiple Complex Needs of the Owner/Operator

Eurostep’s ShareAspace integrated Asset Information Management (iAIM) software product is designed to solve the challenge of sharing asset data across many suppliers and domains in large complex plants and infrastructure in the AEC and EPC industries. ShareAspace iAIM is built on Eurostep’s ShareAspace standards-based digital collaborative platform. ShareAspace is based on ISO standards such as ISO 10303-239 (PLCS) that support the collaboration of asset data throughout its lifecycle.

By basing ShareAspace iAIM on ISO 10303-239 (PLCS), it covers the entire product lifecycle, offers open interoperability with all vendors, and protects the owner/operator from vendor lock-in by addressing multiple data sources:

- Operational and maintenance issues (i.e., Computerized Maintenance Management System (CMMS), Integrated Work Management Systems (IWMS))

- Data Sources (e.g., IoT, SCADA, inspections)

- Product information (e.g., BIM models, point clouds, drawings, documents)

- Requirements management as defined in ISO 19650

CIMdata is impressed with ShareAspace iAIM’s ability to interoperate with many suppliers and technologies throughout the entire lifecycle of assets. Eurostep’s commitment to standards such as PLCS protects the owner/operator from vendor lock-in, offers open interoperability, and provides the resiliency required as vendors or processes evolve over time. ShareAspace iAIM is designed to close the gap between data stemming from different projects that impact the Asset model. ShareAspace iAIM also supports other industry standards within the AEC and EPC industries:

- ISO/IEC 30141―IoT Reference data

- ISO 81346―defines function, location, and product aspects and when combined with PLCS enables traceability between assets and information about assets

- ISO 16739 / IFC―Industry Foundation Classes to support openBIM deliverables

- CFIHOS―information handover specification

- ISO 15926―standard data model for interoperability in capital projects industry

AIM solutions tend to focus on managing the assets for an owner/operator during operation and maintenance. The challenge owner/operators face is that assets are constantly changing and require digital twins with digital threads connected to different sources of truth from a diverse set of changing suppliers. For each supplier, there is a functional breakdown to link the functional requirements and their realization with physical assets. Asset management software solutions typically do not support this through-life traceability. CIMdata’s believes Eurostep’s ShareAspace iAIM offering is at the forefront of the MBSE deployment for AEC/O industry. Its capabilities have been demonstrated via an Interface Management system created for an urban tramway construction project. This system enables the tracking of interfaces and solving conflicts between disciplines and schedules throughout the asset lifecycle.

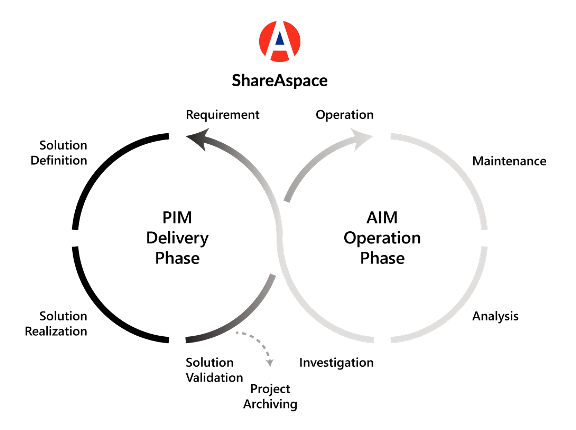

While BIM and other methods are used by many suppliers, primarily in the design phase, and referenced in the construction phase, the project is typically managed with Product Information Management (PIM). The challenge for both handover from design and turnover to the owner/operator is that it’s thought of as a one-time event. Eurostep’s solution closes the gap between the usually disconnected data silos and creates an ongoing asset registry capability that can handle multiple projects and stakeholders involved in several projects as they continue to evolve.

ShareAspace iAIM is designed to enable collaboration across many organizations where different systems are authoritative sources for different information. ShareAspace keeps track of which originating systems loads or updates data into ShareAspace iAIM and ensures that information owned by the originating systems is not updated unless approved by the owner/operator.

The Asset Register is designed to enable “what if” analyses by leveraging the built asset’s Digital Twin where unlimited scenarios can be tested on the virtual asset to ensure optimal decisions. When an extract of the up-to-date Asset Register is required to initiate a local remodeling or upgrade project, ShareAspace iAIM can export data and enable a “reverse handover” from the asset owner/maintainer to EPC companies. This extract can provide semantically rich zones for remodeling and upgrade projects.

A key capability of ShareAspace iAIM and the underlying ShareAspace platform is the ability to integrate multiple companies using multiple technologies where ShareAspace iAIM acts as a collaboration hub providing traceability and through-life configuration management with a flexible data model that supports open and correct access to data.

Conclusion

CIMdata believes that owner/operators in the AEC and EPC industries struggle with secure collaboration across their many suppliers. This supplier mix changes over time, resulting in higher operating costs. We believe AIM is broader than BIM and that owner/operators will benefit by focusing on managing and maintaining assets throughout their lifecycle while enabling a sustainable collaborative environment for managing the assets and the asset suppliers across multiple domains.

CIMdata does not believe Digital Twins are well supported within the AEC and plant industry today. To manage digital twins of assets in a large complex infrastructure with many authoritative sources of information, AIM must manage assets under configuration control and securely collaborate with all the suppliers, providing traceability and end-to-end connectivity across a digital thread.

Eurostep’s ShareAspace iAIM is based on open standards in an open environment and is designed to support the most complex operations enabling assets to be managed across their lifecycle. This prevents information lock-in and provides key functionality supported by MBSE and a strong Data Governance implementation, which enables continual optimization. CIMdata recommends any organization looking to manage large complex facilities and infrastructure consider Eurostep’s ShareAspace iAIM in any technology evaluation.

[1] Research for this commentary was partially supported by Eurostep.