Key Takeaways

- Autodesk Fusion 360 Manage with Upchain (Autodesk PLM) is an easy-to-use SaaS cloud solution for product design and manufacturing (D&M) that deploys quickly, is easy to configure, maintain, and can adapt to your existing processes.

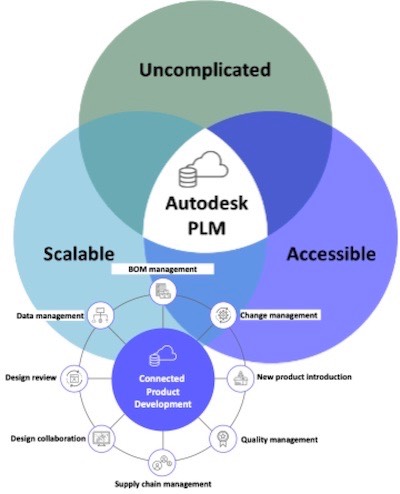

- Autodesk PLM provides connected product development that can grow with your business. It provides multi-CAD data management, product data management (PDM), and a full suite of product lifecycle management (PLM) capabilities modularly delivered that companies can deploy as needed.

- Autodesk PLM enables innovation by improving collaboration across work functions, breaking down siloed work practices, and reducing the duplication of work, thereby allowing companies to do more with less while improving their time-to-market.

- Autodesk PLM drives more operational efficiency by providing increased product development agility as well as improved supply chain agility, while reducing non-value-added processes.

Introduction

Small- to medium-sized businesses (SMBs) are under increasing pressure to perform at an even higher level of efficiency than large enterprises to be competitive and disruptive in their markets. Doing more with less is challenging, especially without the right technology, processes, and the ability to scale. Historically, SMBs considered commercially available product lifecycle management (PLM) solutions to be out of reach. PLM has been perceived, by many, as being overly complex, mired by lengthy deployments, and too costly to maintain for a business with limited information technology (IT) resources. Another concern was that it would require costly changes to processes that already worked. It wasn’t that SMBs did not see the potential value of a PLM solution, but rather they believed that the disruption would be outweighed by any potential benefits.[1]

As SMBs grow, so do their work functions and their need to use common product data across their organization. Without PLM solution enablement, there’s no framework to get the right data to the right people at the right time. As a result, data ends up being duplicated, invalid, disparate, or missing entirely. Functions of a business are typically managing their own data within their own specific solutions.

Oftentimes they resort to spreadsheets and other personal productivity tools. This poor data management practice leads to product data being disconnected across multiple functions such as design, engineering, procurement, manufacturing, quality, service, as well as a company’s supply chain. It results in a lack of collaboration, significant amounts of rework, delays in product delivery, go-to-market inefficiencies across the business, and higher costs. Companies with many siloed work and data practices lack the agility to quicky respond to customer requirements and other existential threats to their business. They suffer a lack of resiliency in how they deal with suppliers, as well as having an increased number of product defects and non-conformities. As companies grow, these disconnects increasingly have a negative impact on their top- and bottom-line.

Companies require a strategic approach that enables them to start small and grow their PLM environment as required. This can be as simple as managing revisions and communicating changes within engineering. As the need to connect people, processes and data increases, additional processes can be added that will increase the company’s efficiency. PLM is not an all or nothing proposition, but rather it provides the ability to collaborate, create, use, manage, and disseminate product-related data as required.

SaaS Cloud for SMB

Today, the ideal solution for a SMB is a SaaS cloud offering for D&M that deploys quickly, is easy to configure, maintain, can adapt to existing processes, but one that also has the flexibility to change and scale as their business grows and changes.

Autodesk PLM offers an uncomplicated highly configurable SaaS cloud solution that users can access from multiple devices, anytime, anywhere with a user-friendly interface. CIMdata finds the user interface to be quite intuitive, which is essential for adoption. It provides configurable tenants that control custom behaviors, views, templates, data validation, workflows, workflow escalations, notifications, and much more. Though this can always be improved upon, CIMdata finds Autodesk PLM to be quite configurable providing the flexibility SMBs require.

Autodesk PLM is open and accessible. In addition to being highly configurable, it is built with modern, open REST APIs that can be integrated with other commercial applications such as ERP, CRM, MES, and other systems and databases with many integrations available through Autodesk’s large partner network.

Autodesk is creating a path to a platform. Autodesk has three industry cloud solutions on their platform: Autodesk Forma for their architecture, engineering, and construction business; Autodesk Flow for their media and entertainment business; and Autodesk Fusion for design and manufacturing. All three, take advantage of Autodesk Platform Services, formerly known as Forge. Autodesk PLM, part of the Autodesk Fusion industry cloud, is an open, accessible, and scalable offering for D&M. CIMdata looks forward to seeing the continuing evolution of Autodesk’s cloud strategy.

Product Development Solution that Can Grow

SMBs require connected product development that can grow with them. It may start with as little as one process and expand as the business does. This could start with data management or PDM within engineering and expand to different modules within PLM as required. Regardless of the starting point, all businesses benefit by the increased collaboration.

Autodesk PLM is designed to scale. It offers a per-user all-in subscription based on a SaaS cloud technology that enables companies to start with one process at a time and easily expand as required. It facilitates innovation with strong collaboration capabilities across work functions, which break down siloed work practices, eliminating duplication of work, and allowing companies to do more with less.

Connected Product Development

Connected product development is connecting organizations’ people, processes, and data, thereby providing them with access to the right data at the right time. All organizations benefit from connected product development. Whether it’s collaboration with multi-CAD, design reviews, change management, or a process such as new product introduction. PLM connects people, processes, and data enabling a company to continuously transform and use product data to realize its business objectives and achieve better top- and bottom-line results.

Figure 1―Autodesk PLM Data and Process Management Capabilities

Autodesk PLM provides multi-CAD data management regardless of the CAD file type (e.g., SOLIDWORKS, NX, Creo, AutoCAD, Inventor, etc.) By using CAD plugins, Autodesk PLM enables users to use tools they’re already familiar with while managing the product data in a centralized source that is open and extensible. CIMdata is impressed with Autodesk’s enhanced multi-CAD capability, which was added as a result of the Upchain acquisition. Autodesk PLM has a native markup capability that can capture all the issues and changes required, enabling quick feedback without the need to add additional proprietary CAD licenses. It allows the user to send notifications, alerts, and set up integrated workflows to automate task assignment and tracking. This increases visibility to internal and external stakeholders. Each user on a project team has easy-to-use to-do lists, providing all the tools for design collaboration and review.

Change is inevitable and is a critical aspect of developing a product. When not handled correctly, uncontrolled change can lead to costly mistakes, including schedule delays, scrap, rework, or potentially even more catastrophic product failures. One of the most beneficial aspects of PLM is the ability to manage product changes. Autodesk PLM delivers change management functionality that can be easily configured to fit a business’ specific needs. It can be used to track item changes with change orders, and approvals with real-time reporting and notifications. Additionally, Autodesk PLM manages change effectivity and material disposition, and tracks workflow history and traceability. No matter how big or small a company is, traceability is required and increasingly important in product development. Users can easily query where-used and affected items. Autodesk PLM allows users to control and access the impact and scope of proposed product changes. CIMdata finds Autodesk PLM's change management capability both comprehensive and intuitive.

In addition to managing change, all manufacturing companies must manage new product introductions (NPIs). This is a process consisting of some form of approvals, a way to manage tasks, and the need to understand progress. Autodesk PLM provides NPI project management capabilities that include an automated phase-gate workflow based on configurable templates. Companies can connect an NPI project to product data (i.e., BOMs, drawings, specifications, etc.) using real-time to-do lists, notifications, and escalations. In addition to providing task management, it provides real-time progress status using dashboards and reporting, which provides excellent visibility and accountability on the status of the project. These are particularly useful features as they provide companies with the ability to focus their resources in the most efficient manner possible.

Operational Efficiency and Agility

All companies are looking to facilitate operational efficiency, increase their product development agility, and reduce non-value-added processes. To support this need, Autodesk PLM provides core data management capabilities, such as the ability to manage CAD file structures and all related items with multi-CAD plugins. This includes visual indicators of changes, versions, and new items. Along with automated part numbering, automated revision control, and permissions for access control, a company can manage all design data in a central repository and maintain secure and proper configuration management across multiple functions of its products and any other documentation throughout their lifecycles.

BOM management is historically one of the more complicated engineering activities. Autodesk PLM’s data management capabilities (e.g., multi-CAD plugins combined with their BOM management) has made BOM management both intuitive and far less time-consuming. Autodesk PLM provides complete item and BOM management with lifecycle controls with integrated visualization. BOM views are configurable and contextual, meaning users can have different views of the same data, which CIMdata calls a multi-view BOM. It includes part classification, an intuitive BOM comparison capability, and can perform material roll-ups, which enables better decisions and accuracy. Autodesk PLM also includes revision effectivity, enabling items to be valid within a given date range, which enables better manufacturing production planning. It also includes “pinning” or overriding revisions including items with effectivity, which is useful when resolving an issue with a specific item. CIMdata found the BOM management module to be comprehensive and easy to use.

Additionally, Autodesk PLM empowers companies to manage quality processes tied to engineering changes (e.g., Return Merchandise Authorization (RMAs), non-conformance reports, and corrective and preventive action―CAPAs). This enables closed-loop quality management, which ties quality back to changes with automatic record creation and full traceability from the initial defect to containment and resolution. CIMdata was impressed with the automated task notifications, reminders, and escalations with real-time metrics using dashboards to analyze trends and improve quality.

As companies grow, they need to manage their supply chain to increase their agility. Autodesk PLM also provides a supply chain portal that permits request for quotations (RFQs) to be submitted, allows sourcing to manage prices between multiple suppliers, and incorporates suppliers in the change management process with accompanying task notifications workflow to increase their efficiency. The supply chain module maintains a history of the supplier’s deliverables for traceability and allows users to schedule, perform, and document supplier audits. Additionally, approved supplier lists are updated in real-time, enabling better coordination between engineering and sourcing. CIMdata is impressed with Autodesk PLM’s ability to manage supplier status and approvals, connect suppliers’ processes such as audits, scorecards, and capability assessments and associate the supplier with the items they’ve supplied for quality, change, and other impact assessments.

Finally, it should be noted that Autodesk complements their own capabilities with an extensive partner ecosystem that develops solutions, and a strong network of trained implementation partners, which is uniquely suited for SMBs.

Conclusion

It is increasingly challenging for SMBs to compete as manufacturing and supply challenges become more complex. Autodesk PLM provides an easy-to-use, SaaS cloud solution for product design and manufacturing that deploys quickly, is easy to configure, maintain, and can adapt to a company’s existing and future process needs.

Autodesk PLM provides connected product development solutions that can scale. It provides CAD data management, PDM, and PLM modules that companies can enable as needed with a per-user all-in subscription based on a SaaS cloud technology enabling customers to go live sooner and achieve faster time-to-value from their solutions.

Autodesk PLM enables innovation with strong collaboration across work functions, which breaks down siloed work practices, and the duplication of work, allowing companies to do more with less. It can enable companies to drive operational efficiency providing increased product development agility, improved supply chain agility, while reducing non-value-added processes. SMBs looking to improve their operations and reduce their time-to-market should consider Autodesk PLM in their evaluation.

[1] Research for this commentary was partially supported by Autodesk.