Key takeaways:

- Product complexity is increasingly a system-of-systems problem requiring effective, efficient systems engineering management solutions from product inception through operations.

- Requirements must be written well, with no ambiguity. They must be shared as they are refined. Duplication of requirements leads to confusion, wasted time, and in extreme cases poor product performance.

- Models of all sorts (logical, functional, structural, electrical, mechanical, equational, etc.) must also be authored well, with no ambiguity. They must also be shared as they are refined. Copies of any engineering items produced within the system engineering digital thread leads to confusion and wasted time.

- Maintaining the systems engineering thread is difficult as the necessary technical processes are digitalized within organizations using many software tools (among them, existing PLM solutions), each with its own file management capabilities which causes copies of requirements lists.

- Researchers have developed ontologies that provide precise languages and standards when authoring and refining requirements, model elements, assemblies, parts, tests, and other relevant data. Computer databases can help enforce semantic clarity when an engineering item’s grammar is defined and precise. Authors can then use these solutions to author the best requirements, models, and associated datum―resulting in clear, concise, precise, and measurable information.

- The Reuse Company (TRC) provides solutions for knowledge gathering, classifying, and sharing, quality enforcement, across many disciplines each with their own specific solutions, e.g., requirements databases, Logical Modeling, CAD, CAE, ALM, etc. TRC ensures interoperability by integrating with these solutions. They provide systems engineers with their SES ENGINEERING Studio―a platform that assures requirements, models, tests, parts, equations, and many other engineering items are authored correctly and shared in a controlled manner keeping them visible all the time.

Successful companies capture and refine the sequence of product decisions needed to make great, profitable products. The sequence, embodied in the digital thread, in which decisions are made during product development, deployment, and operation, is critical to determining a company’s long-term success. It embodies factors like safety margins, compliance, performance, and finances that influence when and how decisions are made. A safety margin example is crash worthiness of automobiles, aircraft, and other products. Decisions for the structure first and foremost focus on protecting the occupants. Performance for certain segments drives sales―whether it is range, acceleration, passenger capacity, or fuel consumption. In this case a lighter car or aircraft can go further, faster. But it also may need expensive materials to maintain structural integrity and protect the occupants. The correct balance between these examples is what drives success. The balance is achieved with a progression of decisions that are heavily influenced by the interactions of requirements linked to the components of the item―the digital thread contains and maintains critical relationships.

Supporting complex decisions during product development and deployment is a systems problem. Systems are best designed around a framework of requirements for a multitude of capabilities: performance, safety, cost, and many others. The problem is to ensure that the requirements are fulfilled and not violated throughout the life of a product. Furthermore, requirements can and do change―which is fine if changes are controlled, fit for purpose, then managed through the lifecycle. It is one thing to define requirements before a product is designed and built, but after a product enters service new complications arise. An important issue is how a system’s defining constraints are maintained, adhered to, and managed as the product is placed in use, and inevitably changes. This requires the concept of a digital thread of the requirements and other product attributes tied to an ever-changing digital twin. Digital threads don’t simply exist, they need a managed environment that understands a product’s requirements and how those requirements form the basis of the digital product definition and how it transforms over time. The Reuse Company provides an interoperability solution to the difficult systems engineering challenges of keeping product requirements and other data elements readily available when making the best decisions.[1]

Systems Engineering and Digital Engineering Definitions

Systems Engineering as a discipline has existed for decades. Computer-based or digital systems engineering improves product robustness because it allows designers to see more interactions among requirements and solutions before a product is produced. However, there is confusion in what various terms mean. The sidebar contains a few key definitions that are used in this paper.

A monolithic PLM system, which expects a single database of product artifacts for decision making, is neither workable nor practical culturally. Rather, a framework of openness and services, coming from many innovative sources, leads to a different architecture for PLM-enabling tools and services―a PLM platform. Within that platform, services for grouping related sets of objects to make the best decisions are required.

While the effort required for creating requirements, models, tests, etc.; sharing them among tools; allocating them appropriately; and maintaining their initial traceability has been reduced, the substantial workload required to maintain these discourages many from continuing this activity throughout a product’s lifecycle, an essential factor for maintaining the digital thread. This undesirable workload when using engineering items is typical of computer-based technologies wherein the original focus is on product artifact creation. Search and simulation have improved the use and reuse of these artifacts but still requires special expertise and effort to perform completely and properly. Yet, as system complexity and the number of artifacts increases, poor requirements and engineering items management, especially supporting traceability throughout the lifecycle, becomes a company’s Achilles heel.

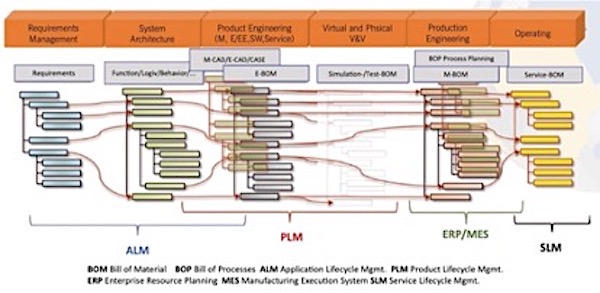

What is needed is in-context viewing and on-demand knowledge exploration to improve decision making. With a live and connected ontology and best in class applications, sharing a context of requirements linked to product elements (models of all sorts, parts, components, assemblies, etc.) creating stable configurations is critical. A configuration is the mechanism which provides a known correlated basis for decisions, even when spanning multiple domains and applications. Dr. Eigner has published his definition and description of the Systems Lifecycle and the various key applications, what CIMdata coins as solution sets, needed when spanning the complete lifecycle. One of his pictograms of the Systems Lifecycle is shown in Figure 1.

Figure 1―Systems Lifecycles need Interoperability between Solutions

(Courtesy Dr. Martin Eigner)

CIMdata’s definition of product lifecycle management (PLM) emphasizes the complete lifecycle of a product and all its related data and processes, from requirements to planning and supply chain participation, then mass production, actual in-use performance, product service and upgrades, and finally decommissioning and recycling. CIMdata’s pictogram, Figure 2, shows a cycle of knowledge and product information which improves a product’s cost effectiveness across its lifecycle. The boundaries between disciplines are ever changing as are the solution sets which often overlap with each other. What is needed is a capability to bridge these disciplines and their solution sets in a controlled way. Asking one discipline to embrace another discipline’s preferred tool just to see their knowledge and understand requirements traceability is not practical. Rather, what is needed is a way for these solution sets to interoperate with each other using well-honed requirements and stable configurations of decision specific knowledge. CIMdata has identified the Critical Dozen Trends and Enablers of Digital Transformation and End-to-End Connectivity is the first one.[2] To achieve efficient interoperability one needs proven end-to-end connectivity. Computers and digital solutions can both help and hurt end-to-end connectivity. An interoperability platform is needed to provide effective end-to-end connectivity. The question then is what should be connected? Simply the knowledge based on experience needed to make decisions. With the evolution of ALM/PLM/ERP/MES/SLM solutions each providing their own automation, some advanced computing has made sharing more error prone when copies of data are used.

Figure 2―CIMdata’s Continuous Product Lifecycle―Many Disciplines Need Collaboration

Systems engineering is benefiting from advances in inexpensive computing and IoT, enabling faster product learning and enhancements. Collecting and using customer usage patterns to influence product development and upgrades are required to stay competitive. Effective system engineering needs to have an interoperability framework which removes confusion and ambiguity―no more copies of files, rather, just views from a well-managed pool of information, even though this information is spread across a company’s digital solutions. This enables more participants, working in their native solutions sets, to provide analysis and applied knowledge when decisions must be made. Engineering becomes more simultaneous and the ability to shorten product development time while lowering costs are achieved, improving a company’s technological advantages. Systems engineering accelerates product development and operations by continuously considering these broader contexts―one that includes the actual product use. The best systems engineering practices need end-to-end connectivity across the primary digital engineering solution sets.

Motivation for The Reuse Company

The founders of The Reuse Company (TRC) realized that file-based exchanges and point-to-point translators could not solve the needs identified above. Instead, what was needed was an ontology broker that could connect ALM, PLM, MES/ERP, and SLM solutions. Dr. Eigner identified the importance of allowing stakeholders to use their preferred computer-based development environment. As long as the broker uses a single ontology and manages stable configurations―sets of related information making knowledge useful, it can better connect disciplines and thus speed product decisions. In fact, this can apply to any needed connection anywhere in the lifecycle.

TRC applied its natural language processing expertise and the desire to foster reuse of knowledge into a solution named SES ENGINEERING Studio (SES).[3] One of the key points of SES is that when a connection is included in the hub all the technical management capabilities are offered to the work products managed by the connection. For example, a connection to a requirements tool (e.g., IBM DOORS) will provide traceability to any other work product in the integration hub including quality management (i.e., correctness, consistency, and completeness), verification, validation, configuration management, decision management, and other disciplines and techniques as they are developed. A connection to a logical model in SysML could then also be used to manage performance and geometric models. By providing the integration hub, TRC has positioned SES to be the interoperability framework that provides an interoperability connection between different sources, and when one of them is textual, like requirements, they use their natural language processing to do magic: understand the text and extract what is needed to interoperate. This technique is applied to all forms of textual knowledge which in turn encourages reuse instead of copying, which is too often the practice with documents and spreadsheets and in PLM and ALM solutions.

While knowledge reuse is common in mature, mass production industries, e.g., automotive, it is just now maturing in others, e.g., defense applications. Effective knowledge reuse happens when best in class authoring tools share the same work-products in a controlled way. Indeed, holistic reuse happens when:

- There is complete access to the content of the reusable asset with no limitations,

- There are means to persist and classify the content in a controlled way,

- Smart searching for the content with no previous information about its existence is supported, and

- It is possible to transform content and then persist it into another source environment.

SES does this with no limitation of the type of knowledge. Cross disciplinarian teams working collaboratively while using the same trustworthy knowledge will develop enhancements and/or investigations from different expert contexts. An interoperability framework encourages many different contexts to be concurrently considered which always improves decision-making. This is the best systems engineering practice that yields robust products.

SES ENGINEERING Studio Features

SES ENGINEERING Studio enables all core business processes for all product disciplines to author, share, and refine knowledge―often reflected in requirements sets, models, tests, BOMs, and other engineering items. It is a platform for digital management of the Systems Engineering Lifecycle.

Figure 3 identifies the broad domains of technical management processes supported by the SES platform that provides connections to quality, V&V, traceability, knowledge, and automation. These domains are key elements of competitive engineering practices, and many PLM/ALM solutions cover these. But different engineering disciplines and skills drive solutions in different ways, for example some focused on milling, others on bending, still others on performance.

Requirements engineering needs to take into account new features realized due to real-time control of the dynamics of mechanical systems. New features are being added to expand a product’s revenue, even after mass production.

PLM/ALM solutions manage some form of digitalization of the technical processes using some amount of automation. They should use one ontology, a consistent way of talking about the product across its whole lifecycle. Authoring and application of requirements, models, parts, tests, and any other items all need a single ontology and the interoperability framework needed to eliminate cloning, copies of uncontrolled versions of knowledge. By providing a solution that offers rigorous change and configuration management of requirements, model elements, diagrams, parts, simulations, and functions, TRC’s SES encourages a model-based ecosystem that is not based on only documents or single ALM/PLM solutions.

Figure 3―SES Connects Tools of the Systems Engineering Ecosystem Offering Verification, Testing, Knowledge through Automation(Courtesy of The Reuse Company)

Concluding Remarks

TRC’s thought leadership and growing successes will accelerate the continuous product lifecycle illustrated in Figure 2 while permitting specific engineering disciplines to use the authoring and database environments which are best for each of them. No time is wasted learning other disciplines’ tools and their unique data models. No time is lost figuring out why copies of files and models do not reflect the same basis. The single ontology enforced by TRC’s interoperability framework makes connections to useful knowledge robust.

TRC has a growing list of customers who are reporting their accomplishments using SES at forums like the International Council on Systems Engineering (INCOSE). Notably Safran[4] has prototype use of SES on their next generation aircraft engines. As more companies become aware of SES, another piece of the landscape for model-based enterprises is realized. Comprehensive, efficient product engineering remains a competitive discriminator. Product development and service processes will be faster with lifecycle concurrent systems engineering. CIMdata believes that companies using SES will be able to support competitive simultaneous, continuous engineering practices.

[1] Research for this commentary was partially supported by The Reuse Company.

[2] CIMdata’s Critical Dozen: https://www.cimdata.com/en/education/educational-webinars/webinar-cimdata-s-critical-dozen-the-top-12-trends-enablers-for-digital-transformation

[3] https://www.reusecompany.com/ses-engineering-studio

[4] SMART Traceability, Davy Masson (SAFRAN Aircraft Engines) and Jose Fuentes (The REUSE Company), at 2022 INCOSE International Symposium