Key takeaways:

- Global trends like social computing, cloud computing, mobile devices, analytics/artificial intelligence, and the Internet of Things (IoT) have dramatically changed our personal and business lives over the last 15 years.

- Smart, connected products are being introduced at an increasing pace across a wide range of industries, retrofit kits make older production equipment smarter and enable new and innovative business opportunities.

- The IoT, and its application to industrial use cases (the Industrial Internet of Things—IIoT), have created new business opportunities and companies need a powerful, flexible IoT platform to best take advantage of them.

- CONTACT Software, a leading independent provider of product lifecycle management (PLM) solutions is addressing this need with CONTACT Elements for IoT, adapting their open, flexible, and standards-based platform to meet the IoT requirements of their broad customer base, making their solution applicable to many different industrial applications.

Introduction

Computing has become ever present in the lives and businesses of people around the world. Social platforms sought to connect us and, like many technologies, have had both positive and negative impacts. Those platforms live on and reach our mobile devices, homes, and businesses using cloud computing. Products in a range of industries are smart and connected, making them nodes on the Internet of Things, as are capital assets as part of the Industrial IoT. All of these technologies, and many others, have changed our lives in the last 15 years.

To take advantage of these opportunities, companies need to adopt and deploy flexible IoT platforms that can support new strategies and business tactics that address market opportunities. One of the key attributes of the IoT/IIoT is the range of standards that define it, coming from a variety of sources. Any IoT/IIoT platform must readily support these open standards. CONTACT Software, an independent German PLM solution provider, is addressing this need with their CONTACT Elements for IoT offering, leveraging their open, standards-based platform to meet these industrial requirements.[1]

Business Success in a Smart, Connected World

In today’s world most people cannot get away from their computing devices. Phones, tablets, and even their appliances have embedded computers to ease their daily burdens. Products in a wide range of industries are smart and connected, as increasingly are the capital assets and equipment used to make those products. The flood of data available from all of these sources demands new ways of analyzing and benefiting from that information, and advances in artificial intelligence (AI) and machine learning (ML) are helping ferret out the pearls in those vast seas of information. These are but a few of the technological changes that have dramatically changed our personal and business lives over the last 15 years.

It was precisely those trends that led the German government, working with industry, academia, and the labor unions to define their vision for Industry 4.0.[2] In short, in an Industry 4.0 world all existing and new assets will be smart and connected (at some level), spanning the built world, including factories, infrastructure, and of course, products.

New products often have the “smarts” built in, but much of the built world, including capital assets, are not often quite so gifted. The Industry 4.0 vision recognized the need to retrofit existing infrastructure and industrial equipment to make it smarter and connecting it in new and innovation ways.

The IoT, and its application to industrial use cases (the IIoT) have created new business opportunities and companies need a powerful, flexible IoT platform to best take advantage of them. In our consulting work, CIMdata has seen many good examples. Just having real-time access to real-world data to support decision-making is huge in industries like manufacturing and logistics. Industrial equipment manufacturers are creating new business opportunities by using predictive maintenance to insure effective uptime. Companies are using insights from operations data to support closed-loop, data-driven compliance and process improvement strategies. Others have closed the loop from product use back to product development to both shorten innovation cycles and to tune new releases to real world needs.

What do you need in an IoT platform? In some respects, an IoT platform must support the convergence of information technology (IT) that powers the business, operational technology (OT) that populates the shopfloors and other operation elements of the business, and engineering technology that supports the product lifecycle from idea through life. These platforms should offer a modern user experience (UX), supporting drag and drop low-code or no-code development of user dashboards that “mashup” data from IoT, enterprise applications, and many other structured and unstructured data sources. Analytics are key to reducing the data to more palatable key process indicators (KPIs) and other user-defined metrics. Users will need to act on dashboard information, so there should be support for relevant business processes to support those actions. Data can come from a wealth of sources, many of which conform to published standards. Any IoT platform should natively support the standards of interest to a particular customer which means, in practice, that most IoT platforms need to support a wide range of standards to enhance their market potential. Platforms used for IIoT applications should readily support edge computing, the use of computing assets within the manufacturing environment that can help capture data as well as distill it for better consumption by the platform and its users. In some cases, IIoT platforms also have to accept data directly from the shop floor from programmable logic controllers (PLCs) on individual machines.

In fact, there are dozens if not hundreds of IoT platforms available in the market. Many are from small startups and are just not that robust. Some lack an industry or technical context and are more about mashing up data to support pilots or simple problems. Product manufacturers, particularly those in industrial equipment or other segments producing long-lived assets, really need to have an IoT platform structured around product development and the product lifecycle.

CONTACT Elements for IoT

CONTACT Software is a leading independent provider of product lifecycle management (PLM) solutions with a strong history of supporting industrial clients in a range of industries, with a heavy focus on discrete manufacturing. Their long-time product CIM Database is delivered based on CONTACT Elements, a coherent suite of building blocks that can be configured to address major collaboration and business needs around the engineering of sophisticated products. Several other recent CIMdata commentaries provide more detail on their company and their platform.[3],[4] More information on CONTACT Software and their offerings is available in the CONTACT Dossier on CIMdata.com.

The CONTACT Elements set of building blocks has expanded over the years as CONTACT has added new capabilities to support customer and market requirements. All of their applications benefit from the underlying platform technologies and services. CONTACT Elements for IoT extends CONTACT Elements, adapting their platform to meet the IoT requirements of their broad customer base. CONTACT is well known in the PLM community for their ardent support of open standards. Thus, their open, flexible, and standards-based platform is a perfect fit in a smart, connected world that relies on a multitude of standards to help realize the Industry 4.0 vision and the convergence of IT, OT and engineering technology. Because CONTACT Elements was designed to support the virtual product, it was straightforward for them to support digital twins, an increasingly important use case related to IoT/IIoT. Figure 1 highlights CONTACT’s view of their offering as an operating system for smart business, spanning the various aspects of IoT and IIoT.

Figure 1—CONTACT Elements for IoT: An Operating System for Smart Business

(Courtesy of CONTACT Software)

While CONTACT has many discrete manufacturers in its customer base, their solution has also been successfully applied in other industries due to its strong project and asset management capabilities. CONTACT Elements for IoT readily supports both IoT use cases around smart, connected products—the internet of products—and IIoT use cases more typical of the shop floor or other capital asset scenarios—the internet of production.

CONTACT’s IoT solution is based on proven, reliable modules. This is important in a market where many IoT platforms come from startups with no track record for reliability. For example, their Closed Loop Engineering and Digital Twin capabilities, essential for companies pursuing product-as-a-service business strategies, leverage their strong xBOM management, CAD data management, and visualization functionality.

CONTACT Elements was designed and implemented to be open. Development is done using Python, a frequent choice for data-science and machine-learning projects that has climbed the programming language rankings to challenge JavaScript and the C language in popularity. CONTACT Elements relies on standard Web services interfaces and REST application programing interfaces (APIs). These are readily available skills in the marketplace for coding talent, helping reduce customer lock-in. Their IoT/IIoT device connectivity is based on standard libraries. Mashups are largely created using no-code function blocks and support for declarative rules. These capabilities allow for flexibility and speed in development, and support tailored for less skilled users. When more complex actions are required users can leverage CONTACT Element’s extensive development and programming environment.

Of course, there are many other advantages to being on the CONTACT Elements platform. CONTACT has long experience with standard interfaces for ERP, most notably SAP, and authentication services. This is important because enterprise systems often provided essential data to IoT mashups. CONTACT InSync, their design system to support developing high quality UX, offers strong capabilities for UI development and branding, including multi-language support.[5] According to CONTACT, their average IoT application contains 7 to 11% “new” components, with the rest natively supported by the platform. The maturity of their code base is a differentiator versus many IoT platform market entrants. It can also help customers to more quickly implement value-added applications, a big benefit in a market where many IoT adopters never seem to get past nice pilot applications.

At its core an IoT (or IIoT) platform is about action. You do not gather data for data’s sake, you want to take more informed action. IoT platforms need to process and analyze data, using traditional analytics or other means like artificial AI/ML, to trigger action. For example, to support closed loop engineering, digital twins are animated using IoT data, and knowledge must travel back up the digital thread to support decision-making and engineering action.

CONTACT Elements for IoT also includes business process automation (BPA) to specify desired actions. For example, users can schedule triggers at desired intervals, such as for scheduled maintenance. They can also trigger events from the edge or a PLC based on KPIs (device is out of specification or requires a maintenance action) using incoming asset data meeting a desired threshold (useful in both IoT and IIoT scenarios). Finally, actions can also be triggered by an external service (e.g., AI/ML mechanism via REST API). A global manufacturer is using CONTACT’s BPA functionality to help standardize their internal maintenance operations. Another machinery provider is offering value-added services: real-time equipment monitoring and provisioning of optimized operating parameters, and including preventative spare part delivery to ensure desired performance.

CONTACT Software has several routes to market for this offering. To date most customers purchased from their direct sales force. The release of a SaaS offering in summer 2021 will expand their reach to both existing and new customers.

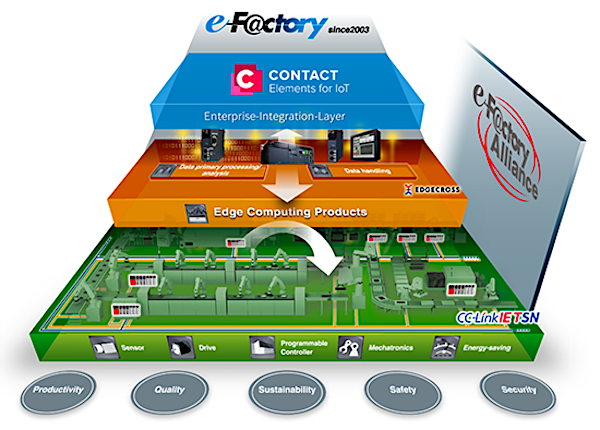

In 2019, CONTACT entered into a partnership with Mitsubishi Electric on the e-F@ctory Alliance that includes the use of CONTACT Elements for IoT as part of joint offerings with the Mitsubishi Electric Factory Automation EMEA division focused on Industry 4.0.[6] Figure 2 illustrates how important CONTACT’s platform is to Mitsubishi’s offering. An example of this collaboration is düspohl Maschinenbau which digitizes production systems.[7] This partnership illustrates the strength of CONTACT’s support for both IoT and IIoT applications.

Figure 2—CONTACT Elements for IoT Central to the e-F@ctory Alliance

(Courtesy of CONTACT Software)

Conclusion

Computers are ubiquitous in today’s smart, connected world and, based on CIMdata’s research and industrial consulting experience, companies from a wide range of industries are leveraging the IoT to achieve both traditional and new business objectives. CONTACT Software, a long-time provider of product lifecycle solutions, created their IoT platform leveraging their CONTACT Elements solution, which is well-suited to both IoT and IIoT applications, in part due to the company’s expertise with industrial assets and their support for digital twins. CONTACT Elements gives them a proven, modular platform and makes it easy to leverage other platform elements in IoT/IIoT applications. The company is positioning CONTACT Elements for IoT as a business platform that can offer an end-to-end solution to support the on-going conversations of IT, OT, and engineering technology. Based on their partnerships and success to date, they are well on their way to realizing their vision.

[1] Research for this commentary was partially supported by CONTACT.

[2] Recommendations for implementing the strategic initiative INDUSTRIE 4.0,” Final report of the Industrie 4.0 Working Group.

[3] https://www.cimdata.com/en/resources/complimentary-reports-research/commentaries/item/12102-contact-elements-a-future-proof-digital-platform-commentary talks about the overall platform.

[4] https://www.cimdata.com/en/resources/complimentary-reports-research/commentaries/item/13274-contact-s-insync-helps-deliver-high-quality-user-experiences-commentary talks about CONTACT InSync, their capability to deliver high quality user experiences.

[5] https://www.cimdata.com/en/resources/complimentary-reports-research/commentaries/item/13274-contact-s-insync-helps-deliver-high-quality-user-experiences

[6] https://www.contact-software.com/en/news/2019/09/smart-factory-contact-software-and-mitsubishi-electric-become-iot-partners/

[7] https://www.contact-software.com/en/news/2020/09/duespohl-maschinenbau-digitizes-production-systems-for-batch-size-1-with-contact-software?L=1