Key takeaways:

- As products continue to become more complex, product development companies need to rely more heavily on suppliers with advanced expertise for sophisticated components and subsystems.

- Managing the collaborative interaction, including engineering changes, among the numerous companies that contribute to a product’s definition, manufacture, and support is essential for bottom-line profit.

- The processes that companies have used in the past are no longer sufficient with increased business speed, agility, and systems complexity. In addition, OEM’s that allow suppliers inside their firewall expose themselves to serious liabilities.

- The technology has now advanced to support a collaboration hub independent of the collaboration partners’ internal systems. Companies would do well to review their own interaction with the supply chain and look toward the future by deploying a collaboration hub approach. Eurostep’s ShareAspace offers an example solution to explore.

Any company that designs, manufactures, and supports innovative and complex products depends on a supply chain that can deliver advanced materials, components, designs, and BOMs. However, the interaction between an OEM company and its suppliers can be challenging. CIMdata has observed that one of the most common approaches seen in the industry today and for many years back, occurs when the OEM invites suppliers inside their firewall, allowing the suppliers to directly incorporate components into the product data repository (Figure 1).

Figure 1—Suppliers Work within OEM Firewall

While this approach eases the burden of integration, it requires that the OEM expend extensive effort to put in place controls using their PLM’s security models or else they expose the product data and IP to serious risks. It is important to prevent partners from getting access to more data than required and having one partner access confidential data from another partner. This could be engineering data but also price data, which is overly sensitive between competing partners.1

Without robust security in-place, when suppliers get direct access to the OEM’s internal product data repository the practice must be based on trust. Even when trust is applied between an OEM and its first-tier suppliers, the collaboration with second-tier, third-tier, etc., suppliers is today so important, that lower tier suppliers need to be an integral part of the engineering change process and not kept at an arm’s length distance by the first-tier suppliers. Increasingly a zero-trust process is required with all suppliers as today’s and future value networks have partners and suppliers moving in and out, supplying several OEMs in parallel. One extreme example of this is when product data is shared in the context of Export Control and ITAR.2 Licenses are then replacing trust.

The Hub-Based Approach

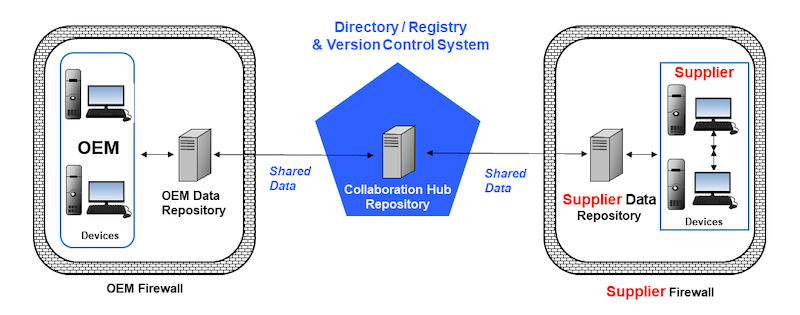

An alternative approach that is capturing the interest of many companies is the concept of a secure, neutral collaboration hub. The hub is a data repository separate from those internal to the company and all its suppliers where each submits product data for integration together (Figure 2). This approach reduces the risk of IP loss or theft because only the data intended for sharing is in the hub repository. An appropriate example of such an environment is provided in the ShareAspace solution from Eurostep (www.eurostep.com).

Figure 2—Collaboration Hub

Integration of data from the OEM and suppliers follows an agreed collaborative process independent of the varied processes each company follows internally and independent of IT systems used inside each collaborating partner. The hub-based approach also adds flexibility as collaborating partners can change and replace their internal systems without impacting all other partners in the hub network. Partners can easily be added as well as being terminated with full control. Another aspect of the collaboration hub, as designed by Eurostep, is that participants could choose to share data in neutral standard formats or proprietary formats, decoupling the hub from their internal systems.

CIMdata believes the collaboration hub approach offers companies many important benefits. Business flexibility is a leading benefit. Because different collaborating partners typically use different internal PLM and CAD design systems, the hub data repository should be based on a rich, powerful, and open data format. Eurostep’s ShareAspace has chosen the ISO STEP standard with AP239 PLCS as the hub data model, covering the complete product lifecycle and generic enough to cover any industry. The choice of hub data can be a standard modeling format such as STEP AP242 or JT in manufacturing industries, and IFC in BIM for the construction industry, as well as general formats of Excel, PDF, WORD, etc.

By working in an environment of a standard data format, the effort allows each contributing company to design using the system of their choice because their proprietary data format will be converted into the standard format before sharing. The OEM gains more flexibility in choosing suppliers and the suppliers’ costs are reduced since they no longer need to have multiple proprietary design systems when working with different OEMs. CIMdata considers these cost savings to benefit not only the suppliers but the OEM as well.

Eurostep’s ShareAspace is a suite of capabilities for collaboration, at the heart of which is the ShareAspace Server that provides the data repository platform for the collaboration hub. The collaboration hub affords each contributor the opportunity to control and track what data has been moved in and out of the hub from their systems. The solution is designed to run on-premise or in the cloud. The cloud SaaS version has a fixed set of processes implemented and is provided as an evergreen subscription service while the on-premise business model can be tailored. Pre-packaged, as well as library- and template-based, means that the on-premise configured solutions are designed for low running cost and ease of implementation and upgrade.

Among the numerous capabilities of ShareAspace Server is support for different levels of Change Control. Users can implement an informal process where changes are merely tracked, and the participants suggest changes through managed conversations. ShareAspace can also provide a more formal comprehensive Change Management solution, where users track requests, proposals, and orders. CIMdata welcomes this flexibility since not all companies and not all products carry the same level of complexity nor require the same level of change control.

ShareAspace provides a full product data management (PDM) suite of capabilities including part versioning, multilevel bill-of-materials (BOMs), and multiple views of the data. It is designed to work in a collaborative environment with multiple contributors using their own systems. The ShareAspace data and file repository is designed to capture and manage information throughout the product lifecycle. The internal database schema is based on ISO 10303 PLCS. It can manage all aspects of product information such as requirements, analysis, design parts, engineering change, and product support.

In one aspect of collaboration that CIMdata believes is critical, ShareAspace offers message management as an informal way of tracking changes, requests, and discussions about product information. It gives a full audit trail and history of the conversations that have taken place among participants.

As a collaboration software, designed as a hub for integration, ShareAspace qualifies as an open system with a data model based on standards and an open REST API to be used for integration.

As products continue to become more complex, product development companies need to rely more heavily on suppliers with advanced expertise for sophisticated components and subsystems. Managing the collaborative interaction among the numerous companies that contribute to a product’s definition, manufacture, and support is essential. The processes that companies have used in the past are no longer sufficient. The OEM that allows suppliers inside their firewall expose themselves to serious liabilities. The technology has now advanced to support a collaboration hub independent of the collaboration partners’ internal systems. Companies would do well to review their own interaction with the supply chain and look toward the future by deploying a flexible collaboration hub approach. Eurostep’s ShareAspace offers an ideal example solution to explore. CIMdata has witnessed several implementations of ShareAspace in production and can confirm the range amongst users, from small companies like WEDA to large organizations such as BAE Systems, Siemens Energy, Volvo, and UK MOD.

1 Research for this commentary was partially funded by Eurostep.

2 ITAR (International Traffic in Arms Regulations)