Key takeaways:

- Human centered innovation, the idea that people need to be able to leverage technology to solve problems, was a common thread throughout Siemens Digital Industries Software Media & Analyst Conference.

- The cloud is becoming pervasive within the Siemens portfolio with the announcement of Teamcenter X and Teamcenter Share, versions of Teamcenter built using the Mendix architecture, and NX Sketch, a microservice implementation of CAD sketching available in NX and Capital, and to be made available in other Xcelerator applications.

- Mendix continues to be central to Siemens’ solution architecture and is being used globally across the Xcelerator portfolio.

- Siemens rich view of the digital twin is delivering solutions (e.g., the newly announced integration between Teamcenter Service Lifecycle Management (SLM) and IBM Maximo) that connect product lifecycles with plant and operations lifecycles creating additional value for both product manufacturers and owner operators.

- Capital, the Xcelerator capabilities for electrical engineering (E/E) systems development, is enabling more sophisticated smart, connected products through its integration of solutions for the entire E/E systems development chain and with the rest of Siemens portfolio, including Teamcenter and NX.

On June 16 and 17, 2020, CIMdata attended Siemens Digital Industries Software’s (Siemens) virtual 2020 Media and Analyst Conference. Siemens reported that approximately 200 Analysts and press attended the two-day event. The event was only 2.5 hours long each day, a tight schedule, particularly when contrasted with past Siemens face-to-face analyst events. Siemens was not able to cover their complete product line and noted in the Q&A that topics such as Solid Edge will be covered in more detail during Realize Live 2020, their user event scheduled for June 23rd and 24th 2020. That event is slated to contain over 70 sessions including customer presentations and more technical detail on many products and topics covered during the analyst event, as well as topics not covered.

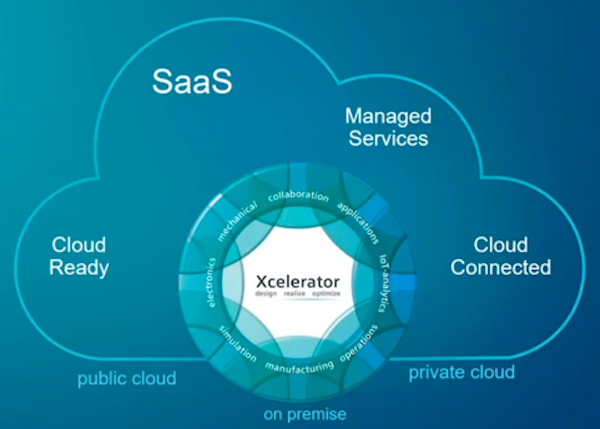

Ms. Brenda Discher, CMO and Head of Strategy, hosted the event and kept it moving with well-timed Q&A, as well as periodically recapping the key points Siemens wanted to make sure the attendees captured both within this event and in the upcoming Realize Live 2020. Ms. Discher identified Siemens differentiating characteristics to be “Comprehensive Digital Twin, Personalized Adaptable/Modern, and Flexible Open Ecosystem.” All the presentations highlighted how Siemens’ capabilities in these three areas were proving valuable to customers. Key to delivering these differentiators is Mendix, a relatively recent acquisition that has become central to Siemens’ strategy and solution architecture. CIMdata is impressed with how quickly Mendix has been adapted from its largely business and IT background to be a core enabler of product development, manufacturing, and service capabilities as illustrated in the portfolio architecture diagram in Figure 1.

Mr. Tony Hemmelgarn, CEO of Siemens Digital Industries Software, gave the opening keynote focused on human-centered innovation. His remarks emphasized how Siemens’ customers are adapting to the disruptive changes that have hit the world in 2020. He described how VinFast, the Vietnamese automotive startup and headliner from last year’s analyst event, was able to transform their car factory to ventilator production in three weeks using the Siemens’ Xcelerator portfolio, the branding that Siemens unveiled for their solution portfolio at last year’s analyst event. Mr. Hemmelgarn talked about how Siemens offerings were supporting the restarting of factories, showing a video describing how the multiple Siemens solutions have been used to create an actionable digital twin to help ensure production cells safely supported social distancing. *1

When an issue was found within the simulation the plant design was quickly changed to ensure human and process safety. In another example, he illustrated how Land O’Lakes, the dairy products manufacturer, is using Mendix to create user-friendly online portals for customers and suppliers. Mr. Hemmelgarn also spoke of Rurok Industries, a mountain bike startup, and how they have leveraged Siemens’ Additive Manufacturing network to bring their new products to market as part of their flexible, open ecosystem support. As part of his keynote, Mr. Hemmelgarn also announced two new products, Teamcenter X and Teamcenter Share. Teamcenter X represents the next generation of Siemens’ very successful Teamcenter solution. Teamcenter X and Teamcenter Share are both cloud-native solutions and were covered in more detail in a later presentation by Mr. Joe Bohman, Senior Vice President Lifecycle Collaboration. Mr. Hemmelgarn’s final announcement updated the audience on their progress with their IBM partnership that includes an integration with Maximo to support service lifecycle management (SLM). CIMdata was pleased to see the two new solutions Siemens introduced and the customer applications being built on their solutions.

Mr. Bohman kicked off his presentation with a deeper dive into their announcement of Teamcenter X, a microservice-based SaaS solution. It is a full implementation of Teamcenter and directly compatible with the current on-premise version. A key point CIMdata noted was that an on-premise implementation can be directly moved to Teamcenter X with little or no change. We look forward to probing deeper to understand any limitations that might exist such as integrations to on-premise solutions and custom applications. Mr. Bohman provided details on Teamcenter Share, a design collaboration-focused application available later this summer. It will support multi-CAD integrations and synchronization, including product structures using cloud file services such as Dropbox. While targeted at small to mid-sized businesses, CIMdata expects Teamcenter Share will be adopted by large enterprises as well, due to its ease of use and support for robust security. Mr. Bohman noted that Mendix is being used to develop all the new solutions as shown in the current Xcelerator architecture diagram shown in Figure 1.

Figure 1—The Siemens Xcelerator Architecture Diagram (Courtesy of Siemens)

Mr. Bohman then reviewed some new Teamcenter features including multi-domain BOMs that connect mechanical, electronics, software, and simulation data into a complete product configuration. He also mentioned their new built as-a-service configurator application, which is available in Teamcenter and is also a standalone module that has already been integrated to Capital. CIMdata has always been impressed by Siemens long-term support of their customers’ investments. We think the move to microservices will have a significant and positive impact on the digital transformation projects being executed by their customers. The ability to configure microservices into custom solutions using Mendix while protecting customer investments in applications and data should be well received. Mr. Bohman is also responsible for Polarion, Siemens’ ALM solution, and he noted that Polarion X is also being released as a cloud-native solution tightly integrated with Teamcenter X through the multi-domain BOM capability. As products become more software-enabled, CIMdata believes that having ALM and core PLM implemented on the same platform will be crucial to achieving the collaboration needed to effectively and efficiently deliver market leading innovative products and services. Finally, Mr. Bohman introduced Smart Discovery, a new feature that enables more robust search. In a demonstration, he showed how attributes and geometric relationships can be used to quickly answer complex questions such as to rapidly identify the cameras located near sources of electromagnetic interference in a vehicle.

Mr. Stuart McCutcheon, Global Vice President–Global Sales & Customer Success, reviewed recent solutions using comprehensive, actionable digital twins and presented case studies from Wärtsilä, Bye Aerospace, the James Webb Space Telescope, Renom, General Motors (GM), Space X, VinFast, and Lion-Electric. As part of his presentation, he offered details on closed-loop product and factory/plant digital twins and described how these different lifecycles intersected in production. What CIMdata found impressive in the customer examples was how the digital twin is being used to solve business problems ranging from servicing wind turbines and optimizing wind farm performance at Renom, to managing GM’s global dimensional information system providing both product and plant views of the digital twin.

During the Q&A, Siemens discussed the NX Sketch capabilities currently being used within NX. CIMdata is looking forward to seeing how potentially ground-breaking capabilities such as NX Sketch and the previously released visualization microservices can be used to bring new and robust solutions to the market faster.

Day two of the event focused on the cloud, electronics, and SLM. Mr. Ray Kok, Senior Vice President, Cloud Application Solutions, positioned Siemens cloud offerings and strategy using the graphic shown in Figure 2.

Figure 2—Siemens Cloud Business Architecture (Courtesy of Siemens)

Mr. Kok opened by revisiting Decathlon, a French sporting goods company discussed at previous events, emphasizing their success using the Siemens Additive Manufacturing Network. They started with simple prototypes but have moved to higher value-added applications. In another example he discussed Aquaculture 4.0, supporting a Singapore-based Smart Floating Fish Farm, using Siemens converters, PLCs, flow meters, SCADA systems, and MindSphere for IoT. Finally, Mr. Kok spoke of a Spanish customer managing water infrastructure who uses Siemens offerings to optimize both fresh and wastewater management using predictive maintenance. CIMdata was impressed with the variety of domains and scope of cloud-based customer implementations of various Siemens solutions. Mr. Kok made clear that Mendix is a critical platform used to solve these complex customer problems and referred to the architecture shown in

Figure 1. His remarks continued with a review of the new Teamcenter solutions, including introducing a new application, PartQuest, that supports the electronic component digital thread. By leveraging cloud connections, it enables traceability of the parts and components used back to the manufacturer and guarantees authenticity with blockchain technology. Blockchain is an area of interest for CIMdata, so we will be digging deeper to understand how the PartQuest digital thread is configured, functions, and how it performs at customers.

Two important points identified in Mr. Kok’s presentation were the critical nature of Mendix support across the Siemens platforms such as Teamcenter and MindSphere to create and maintain digital threads, and the compatibility of Teamcenter with Teamcenter X. Legacy implementations of Teamcenter can be transferred to Teamcenter X and, most importantly, Siemens will assume responsibility for customizations using its managed services. This is a big deal as the cloud-native Teamcenter X will be upgraded by Siemens.

Perhaps the highlight of the event was the presentation delivered by Mr. Martin O’Brien, Senior Vice President & GM Integrated Electrical Systems. He discussed how Capital now addresses the many facets of E/E systems in modern products and infrastructure. The core Capital flow has focused on electrical distribution, harness design, and documentation. Capital E/E Systems Development adds system architecture design, software implementation, and network communication to the solution. An interesting example that Mr. O’Brien described was how by splitting an automotive door ECU into two ECUs, an OEM was able to reduce the total cost by simplifying the wiring required within the door. Capital made it easy to partition functions across the ECUs and generate the appropriate wiring artifacts.

A presentation on Service Lifecycle Management (SLM) was delivered by Mr. Yishai Barak, Director, Service Lifecycle Management. Like the preceding speakers, Mr. Barak opened with a series of customer successes focused on maintenance, repair, and overhaul/operations (MRO) and the service lifecycle. He reviewed the well-understood benefits of a well-defined and implemented SLM approach and how it impacts cost, quality, and customer satisfaction across several asset intensive industries such as aerospace, oil & gas, and industrial equipment. His presentation then went into detail about how IoT and analytics are improving operations and even leading to product-as-a-service (PaaS) business models. Mr. Barak noted that Siemens is proud of their ability to link the product lifecycle to the plant or asset lifecycle, and how their implementation of a comprehensive digital twin strategy enables improved collaboration between product producers and owner/operators. Capital assets (e.g., airplanes, machinery, factories, oil refineries, etc.) follow a product lifecycle similar to any designed “product,” but are usually more focused on the service/operations phase of the lifecycle. SLM is a solution used to manage the capital asset lifecycle (i.e., equipment makers and the plant lifecycle), by combining forces with IBM and its leading MRO solution Maximo. With the integration of their respective solutions, Siemens is using the Xcelerator portfolio to address the product/plant lifecycle, and, perhaps most importantly, the handoff or integration between the lifecycles as shown in Figure 3. By developing this integration with Maximo, Siemens is able to close the loop between product and plant, helping customers reduce costs, improve uptime, and extend an asset’s useful life. CIMdata is happy to see this end-to-end integration become available and believe it will have a big impact on both OEMs of equipment and the owner/operators of capital assets, but more importantly allow product improvements that enable a circular economy.

Figure 3—Siemens Closed-Loop SLM (Courtesy of Siemens)

Siemens presented a huge amount of information during the two-day, five-hour event. They announced a set of cloud-based technology and solutions and showed how customers are using some of Siemens’ solutions to improve their businesses. The cloud is becoming deeply embedded in Siemens’ solution portfolio and is a clear path forward. While using the cloud has often seemed like a cost reduction initiative, with ambiguous improvement opportunities, the recent remote work issues driven by the COVID-19 pandemic and what Siemens presented to respond to these new requirements are showing that the benefits of cloud delivery actually go way beyond cost reduction.

Siemens Xcelerator portfolio was well represented at this event. Siemens showed how their products including Teamcenter, Capital, and MindSphere, leveraging Mendix, can quickly solve complex business issues at industrial companies. CIMdata recommends watching a replay of Realize LIVE 2020 and checking out Siemens’ full portfolio. It incorporates a suite of modern, implementable technologies that can solve real world problems.

*1 For more, see CIMdata’s recent highlight at https://www.cimdata.com/en/resources/complimentary-reports-research/commentaries/item/13827-siemens-introduces-workplace-distancing-solution-highlight