Key takeaways:

- XSB, Inc. enters the product development market with a solution that brings engineering documentation into the digital thread of design and manufacturing.

- XSB’s SWISS solution builds an AI-enabled knowledge graph of technical information that drives the design, manufacturing, and support of a product. The knowledge graph is integrated with popular PLM systems.

- SWISS creates interoperability between related documents and related concepts within documents, reducing the time that engineers spend looking for answers.

- SWISS can show users what has changed in product-supporting technical specifications from inside and outside the enterprise, thereby reducing the use of outdated information and improving compliance.

- SWISS facilitates new document creation using (and reusing) data from authoritative sources, with live links back to those sources for constant change monitoring.

The term Digital Twin has risen to the forefront of interest in the product development and manufacturing industry. A digital twin is a virtual replica of a physical product, process, or system. It bridges the physical and digital worlds. CIMdata defines the digital thread as the communication framework that allows a connected data flow and integrated view of an asset’s data (i.e., its digital twin) throughout its lifecycle across traditionally siloed functional perspectives. So far, companies and products that enable the Digital Thread have focused almost exclusively on an asset’s design data (geometric dimensions, tolerances, etc.), but have largely ignored other key elements of the asset including its critical supporting documentation such as work instructions, compliance requirements, and more. Most of this support documentation remains in static formats (such as PDF, Word, or even print) which has created steep challenges for engineering organizations aiming to reduce manual labor and increase automation. *1

XSB, Inc. is a New York-based software provider that provides solutions that they position as “systems of intelligence.” *2 Their implementations use artificial intelligence (AI) technology that leverages the attributes of manufactured products, such as parts, materials, processes, and even prices to give users previously unknown insights that help them make better decisions faster. The XSB solutions combine and formalize a company’s internal proprietary data sources plus external industry data to help:

- Commercial and government procurement officers buy smarter

- Parts managers reduce duplicative and obsolete inventory

- Product designers and manufacturers avoid errors, reduce manual labor, and manage change

The Problem

Conventional product design and manufacturing is centered around product geometry, dimensions, and tolerances, but not semantics. The tools used to engineer products don’t intelligently interact with non-geometric information such as text, tables, graphs, equations, images, or references to other content. This static text-based information often identifies critical information about the product, such as a material type (and potential hazardous contents), exceptions and exemptions, manufacturing work instructions, compliance to industry standard requirements, and test methods.

Today, static documents for design and manufacturing standards, be they proprietary or public, force designers and manufacturing engineers to expend considerable effort to locate, copy/paste, re-enter, and interpret technical data leading to redundancy, inconsistencies, and errors. Company documents, industry standards, and other external inputs can change unbeknownst to the engineer, resulting in design and manufacturing problems. For example, the manufacturing work instructions of a product component will often reference an industry standard process. However, given the rate of change seen in manufacturing processes today, especially for additive manufacturing, the specification may change at some point in the product lifecycle. The manufacturing engineer unknowingly uses out-of-date information, resulting in a less than optimal production process, or worse, compliance and liability issues.

The SWISS Solution

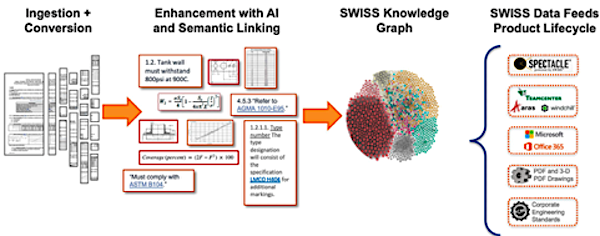

The SWISS solution expands the digital thread view of engineering requirements to non-3D geometric product data by enabling documents as “intelligent digital data” within the virtual product under development. Users employ SWISS to import their company-proprietary documents as well as public and industry standards, while SWISS automatically generates semantic tags and indices for those documents. In doing so, as shown in Figure 1, SWISS builds a linked data model—a knowledge graph—of smart, connected assets that are change-aware within the enterprise and optionally, within the PLM system. SWISS ensures that every concept in the knowledge graph knows its meaning, its status, and its relationship to other data in the graph, resulting in an intelligent system of interoperable data that can communicate changes up and down the product lifecycle.

Figure 1—SWISS Transforms Documents into Digital Assets (Courtesy of XSB, Inc.)

Once the SWISS knowledge graph is established, it can proactively feed other applications with SWISS data, and other systems may access and query the knowledge graph through the SWISS application programming interface (API). XSB reports they currently have integrations with Siemens Teamcenter, PTC Windchill, ARAS Innovator, and Microsoft Word.

The SWISS knowledge graph also creates new interoperability between data sets. For example, if company-proprietary documents reference public documents or industry standards (such as ASTM, MIL, SAE, ISO, and others), SWISS identifies those references automatically and creates clickable links between the data. The resulting network of documents, data points, and concepts helps users pinpoint the exact information they need to get to the next step in their workflow. Just as important, it shows them “what they don’t know:” previously unseen relationships that provide better insight into design and manufacturing dependencies. Together, the unique data view helps organizations get their product to market faster, with lower cost, and better compliance.

User Interaction

Industry best practice dictates that prior to sending a technical data package (TDP) of part models and supporting documentation to a supplier, the sending organization should review all the technical documents and specifications referenced in the data package. With today’s conventional methods, this investigation could take days or even weeks to verify all the references and make sure everything is up to date. Even after this tedious manual check is complete, it can become obsolete quickly due to changes happening every day with internal and external documentation. As shown in Figure 2, using SWISS, the user simply queries the solution to trace all references and report on their status—valid or changed since the TDP was authored. The user can then easily ask SWISS to display the changed specifications showing what had been added and deleted to determine if those changes affect the current product TDP. This process of impact assessment can be reduced from days to minutes.

SWISS also addresses a daily challenge that is the source of significant manual labor and frequent user error. Design and manufacturing engineers regularly create new internal documents (for example, a test plan) which often contain or reference material from other internal or external documents (like MIL Specs or industry standards). Extracting this source material from static text formats into the newly created test plan entails the age-old habits of copy/paste and manual re-key, both of which are tedious, time-intensive, and have the potential for human error. SWISS provides a patented method of dragging and dropping data from one document to another creating a perfectly rendered view of the mashed-up source material along with a live link to the authoritative source. That live link also serves as a constant change monitor; when changes occur at the source, a notification appears automatically on the new test plan. See Figure 3.

Figure 2—SWISS Display of Changed Specification Using the Spectacle Browser (Courtesy of XSB, Inc.)

Figure 3—Display of Test Requirements Created within SWISS Using Authoritative Source Material—the Color-Coded Flags Indicate What has Changed in the Source Materials (Courtesy of XSB, Inc.)

Summary

As product development companies continue to evolve their implementation of the digital twin and its digital thread, they would be remiss not to include the wealth of technical documentation behind their designs and manufacturing processes. Without proper validation of the specifications upon which their products are developed they have an incomplete digital twin. They run the risk of, at best, of a less optimal product and, at worst, introducing errors into the product, which can then lead to rework or, worse yet, product liability.

CIMdata recognizes the efforts and the ingenuity of the XSB SWISS organization to deliver a highly innovative solution for design and manufacturing engineers and many other users of product data. Companies that wish to reduce their time to market, minimize error rates, and eliminate tedious manual labor would do well to consider SWISS as part of their digital thread efforts.

*1 Research for this commentary was partially supported by XSB, Inc.

*2 See: https://news.greylock.com/the-new-moats-53f61aeac2d9