Key takeaways:

- The attendees were very open in sharing their positive experiences with the DFMPro solution.

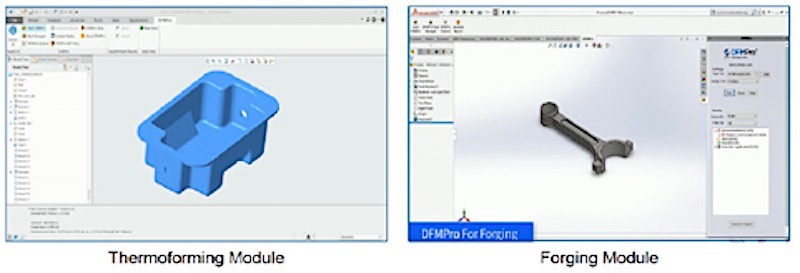

- HCL introduced new Thermoforming and Casting modules in DFMPro.

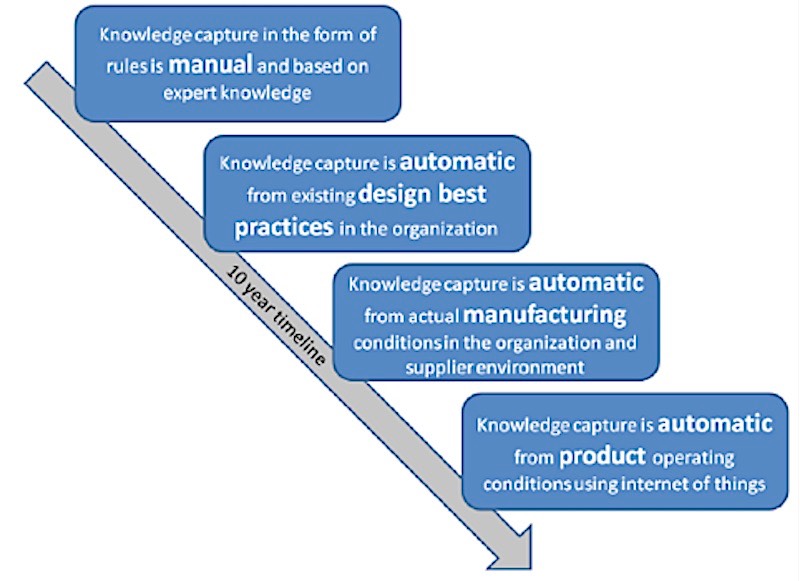

- HCL shared their vision of a future where knowledge capture will be automatic based on actual product operating conditions.

CIMdata attended HCL’s DFMPro annual users meeting, DFX Insights’19, in Detroit on April 16, 2019. The one-day event was focused on HCL’s DFMPro software solution created to help designers check their product designs for manufacturability and assembly, allowing problems to be found and corrected early in the product design process. DFMPro offers a suite of rules-based checks to identify product areas that are difficult, expensive or impossible to manufacture and a framework for users to add their own. The event was positioned for users to share best practices and foster a deeper understanding of the Design for Excellence (DFX) approach which leads to business success. Attendees from automotive, medical devices, industrial machinery, and consumer products were on hand to proactively participate and discuss the benefits they have obtained from the DFMPro toolset and to learn from HCL the future enhancements planned for the solution.

Mr. Nambi Chandrasekaran, Global Head – Geometric Tech Products, welcomed the attendees and positioned the day’s intent as an opportunity for the participants to learn from HCL experts’ and peers’ DFX implementation tips and best practices, share success stories, and network with product design experts. Mr. Swadhin Bhide, Director of Product Management for HCL, gave the opening keynote. He set the stage by reporting the results of a survey HCL conducted in late 2018 in which an overwhelming 92% reported that their products increased in complexity over the past five years. The leading causes were more intricate mechanical designs, added electronics, and the need for different materials.

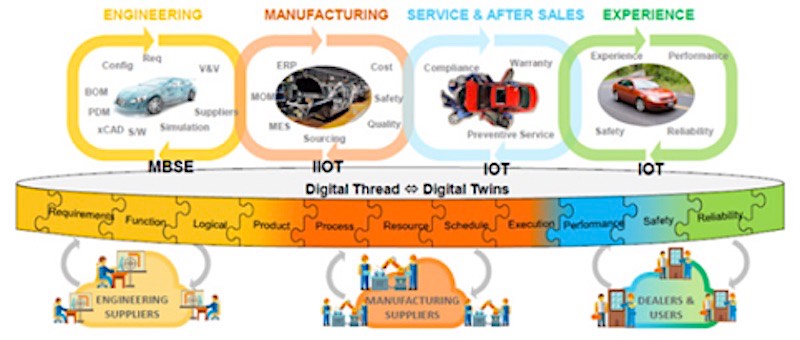

Figure 1—Digital Transformation Requires a Product Innovation Platform (Courtesy of HCL)

In addition, Mr. Bhide spoke of the Digital Transformation occurring in all industries as enterprises seek to adapt to new technology. CIMdata has also recognized this trend and has noted that digital transformation is the expansion of digital technology in business processes that change how companies operate and provide value to their customers. Mr. Bhide explained HCL’s position that digital transformation will require a Product Innovation Platform (Figure 1 above) supported by a Digital Ecosystem. He elaborated that a “Design for eXcellence” strategy is an integral part of the Digital Process Chain.

Mr. Bhide also reported on the results of a customer survey they conducted in 2018-2019. A number of insights stood out to CIMdata, including:

- 53% indicated that their product development cycle is less than 12 months

- 60% of executives indicate that designs are shared with suppliers before they are frozen

- 78% track ECO/ECNs and 70% reported costs of more than $5,000 per ECO/ECN

- 73% of executives report that design rework happens up to 20% of the time because cost estimates do not meet expectations

- 40% of executives name product quality as the factor driving the use of DFX practices

Throughout the day speakers from a US automotive supplier, a medical device manufacturer, and a consumer products producer all described their use of the DFMPro suite of tools and the benefits they derive from them in their companies. Most spoke of their company’s experience in introducing DFX into their organizations and the benefits they have been able to gain. One of the more interesting user presentations spoke of the steps they took to enable DFX by first naming an internal “champion” to lead the introduction and then forming a committee to define the most valuable rules they would implement. That was followed by creating start-up guides and demonstration videos for new users of DFX. Their attention to detail impressed CIMdata and their ideas mirrored the advice CIMdata gives their own clients.

Mr. Yogiraj Dama, and Mr. Prashant Chandanapurkar from the product management team at HCL Technologies took the stage to present recent enhancements to the DFX tool suite. At the top of their agenda were new modules for Thermoforming and Forging. See Figure 2. These add to the previously existing support for injection molding, sheet metal, machining, casting, welding, tubing, additive manufacturing, and assembly processes.

Figure 2—DFX’s Newly Added Modules (Courtesy of HCL)

They then described new rules for their additive manufacturing and machining modules, as well as assembly. A DFX Analytics addition and improved user experience were discussed and drew positive audience reactions.

Mr. Dama and Mr. Chandanapurkar closed the conference by sharing HCL’s DFX vision and direction for the future. While being careful to qualify their statements that these were not commitments for delivery and could change at any time, they presented their vision of the future wherein knowledge capture moves from manual to automatic, as illustrated in Figure 3.

Figure 3—Future Strategy for Knowledge Capture (Content courtesy of HCL)

Conclusion

CIMdata was impressed by the friendliness and openness of the DFX client attendees at the conference to share their experiences. One could see that this was a “family” of design engineers from different industries all participating in a common journey to better their product development environments. CIMdata was pleased to see the improvements to DFMPro and the DFX framework that have occurred over the past year and is supportive of HCL’s future vision.