Key takeaways:

- Dassault Systèmes with its 3DEXPERIENCE platform, integrated industry end-to-end process solutions, and supporting apps, are in the forefront of realizing the future simulation ecosystem, parts of which they already have available today.

- CIMdata a believes that Dassault Systèmes continues to innovate in Additive Manufacturing using it as part of the end-to-end processes in their solution and their 3DEXPERIENCE Marketplace.

- Dassault Systèmes’ “POWER’BY” strategy includes easy integration of third-party solutions into their simulation ecosystem.

- Industry's next big challenge remains: to enable the cultural change required to make better use of already available simulation and prediction technology. CIMdata believes that Dassault Systèmes is well prepared to help their customers in this transformation.

With its third “Science in the Age of Experience” conference, and second to be held in Boston, Dassault Systèmes clearly underlined the progress it has made in aligning its solutions by industry verticals while shifting away from their previous mainly brand-focused approach. Overall, the event’s focus continued to be very much on science; how science drives innovation and can support the digitalization efforts of businesses across the various industries. This could be seen in the adjusted structure of the conference and its emphasize on science under the general theme of “Science is…”:

- Material

- Personal

- Discovering

- Sustaining

Mr. Bernard Charlès, Vice-Chairman and CEO of Dassault Systèmes, highlighted Dassault Systèmes’ long-term commitment to science and simulation investments to provide the proper technology to support its customers’ efforts and continue to help the vision for harmonizing product, nature, and life. Mr. Charlès stated that today “the value is in the usage of the product and not just in the product anymore.” He believes with the Age of Experience a new “industry renaissance” has begun—similar to changes that started over 500 years ago after Johannes Gutenberg invented the printing press. Printing technology made knowledge readily available to a much broader audience. According to Mr. Charlès, “The new book is the Experience.” Today’s technology advances make it easier to bring virtual and real life closer together, making science part of engineering, but also help democratize their use. This will make “experience” part of the daily routine for a much broader audience as well. Mr. Charlès believes this will help accelerate the innovative processes within various industries.

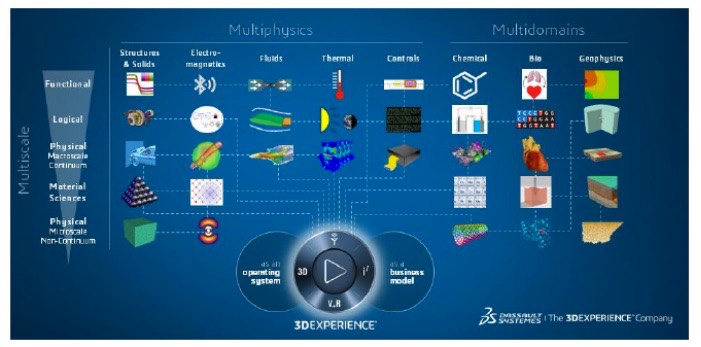

This vision is realized step-by-step through advances in and delivery of the 3DEXPERIENCE platform. It is evolving into a platform for knowledge and know-how providing an operational backbone (operating system) and business model at the same time, while bringing the various multiscale, multiphysics, and multidomain apps together (see Figure 1).

Figure 1—The 3DEXPERIENCE Platform—A Platform for Knowledge and Know-How

(Image Courtesy of Dassault Systèmes)

In addition, to more than 60 end-user presentations in the industry breakout sessions, the event included keynote presentations by:

- Nobel Prize winner Dr. Michael Rosbash from Brandeis University on circadian rhythm

- Dr. Bruno Ferre from Digital Orthopedics on the transformation of the planning and execution of orthopedic surgeries

- Dr. Byron Pipes from Purdue University on advanced composites and Purdue’s vision for simulation 2040

- Mr. Nyle Miyamoto from Boeing on additive manufacturing and how it helps build aerospace’s future

These different presentations all helped to clearly demonstrate not only the connection between science and engineering of real-life products but also the advances already made to enable this linkage in today’s environment.

A major enabler for this linkage is simulation. Dr. Byron Pipes stated, “simulation is the language for innovation.” His comment was not only focused on product engineering but closely incorporates manufacturing and all other aspects of the supply chain. When speaking of the simulation ecosystem 2040, Dr. Byron Pipes suggested it would contain the following elements:

- Accessibility

- Adaptability

- Interoperability

- Traceability

- User friendliness

- Pervasiveness

He continued to suggest that those will be supported by end-to-end solutions focused on the usage of apps and a fully enabled digital thread.

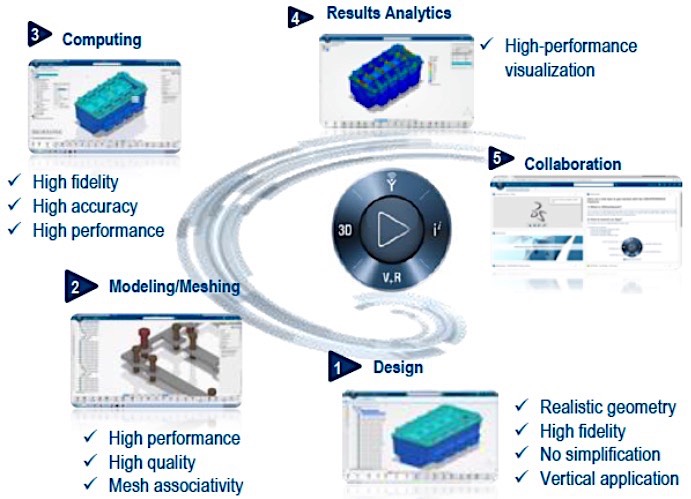

Dassault Systèmes addresses this trend and need through its 3DEXPERIENCE platform and related apps to create a cross-industry innovation ecosystem. This allows users to create industry specific end-to-end solutions on the backbone of the platform.

CIMdata believes that Dassault Systèmes with its 3DEXPERIENCE platform with their integrated industry end-to-end process solutions and supporting apps is in the forefront of realizing such a simulation ecosystem. Throughout the conference numerous examples were provided detailing these industry solutions.

In addition, Dassault Systèmes continues to enhance the underlying solver technologies and align them with the advances of the industry specific solutions. One example is the “to-be” end-to-end process for internal combustion powertrain engineering shown in Figure 2.

Dassault Systèmes claims considerable progress in additive manufacturing (AM) as part of the multiscale / multiphysics challenge in their presentations. Besides discussions and presentations during the conference itself, an AM Symposium and Hackathon were featured co-located events running during the conference. Dassault Systèmes also believes that AM is a key enabler for design innovation. CIMdata believes that Dassault Systèmes continues to innovate in this area further using end-to-end solution processes and their 3DEXPERIENCE Marketplace.

Figure 2—"To-Be" Process for Internal Combustion Powertrain Engineering

(Image Courtesy of Dassault Systèmes)

Dassault Systèmes’ focus on the end-to-end solution processes will help their users in their efforts to democratize simulation as it brings areas like CAD, CAM, and CAE together. Their approach not only allows but also fosters thinking beyond one’s own four walls, helping to break down silos. In addition, Dassault Systèmes’ “POWER’BY” strategy simplifies integrating third-party solutions into the Dassault Systèmes simulation ecosystem which is critical since most companies have a heterogeneous mix of simulation tools.

While the technology now available is getting much better and faster in being able to support levels of sustainable innovation through the end-to-end solution approaches, other elements start to find their way into the 3DEXPERIENCE ecosystem which will allow users to move beyond those initial levels of innovation maturity. Such elements include the enhanced search capability by enriching data with cognitive technologies and the 3DEXPERIENCE Twin, Dassault Systèmes’ implementation of digital twin capabilities. CIMdata is looking forward to progress in those areas over the near future which will allow for an even more comprehensive offering to support businesses further in their efforts in digital transformation.

Still, it was highlighted in several discussions that it is paramount that business cultures within industry still have a long way to go to make proper use of the available technology. Thus, as CIMdata highlighted in previous commentaries, one of the main challenges remains cultural change, fundamentally modifying the ways in which companies operate in order to leverage scientific modeling and simulation to make sustainable innovation happen.

In CIMdata’s opinion, with the renewed focus on industry specific end-to-end solutions, Dassault Systèmes continues to display a compelling vision of how science can and will enable sustainable innovation. The major challenge CIMdata sees going forward is how to gain the momentum needed to apply cultural change to make full use of the technology which is already available. CIMdata believes, Dassault Systèmes to be poised to help their customers in this transformation.